- Clean all the components of the gear-

box and gear selector assembly, and

additionally the crankshaft, using any

degreasing agent.

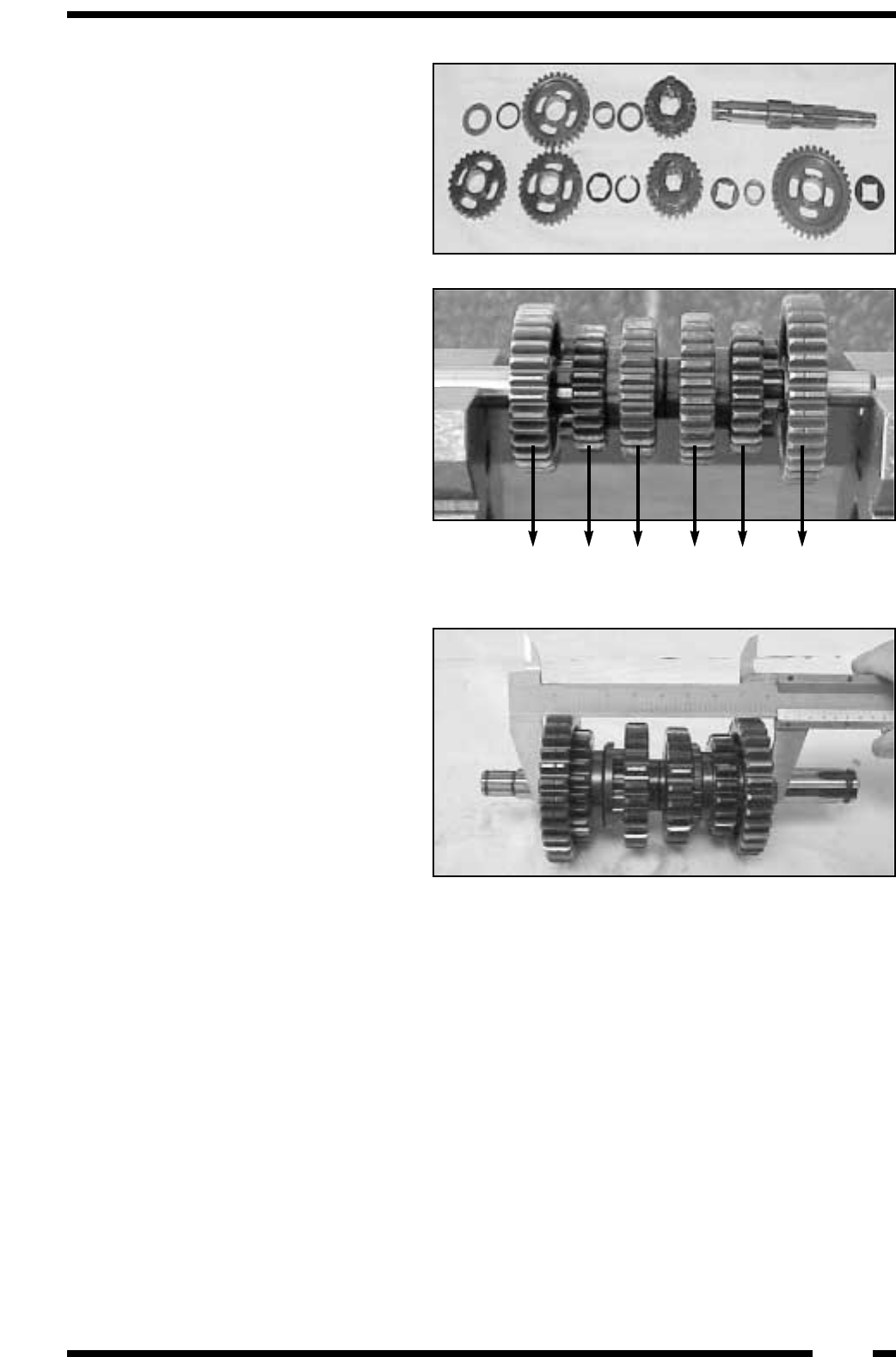

- Re-assemble the gearbox secondary

shaft, taking particular care to ensure

correct assembly of all the compo-

nents, in order to avoid malfunction

and seizing.

- Fit the gearbox assembly into the

right hand crankcase half, (the pri-

mary and secondary shafts should be

inserted meshed together at the same

time).

- First check the overall width of the

secondary shaft sub-assembly inclu-

ding the adjusting shims on each

side.

Overall width of secondary shaft:

MAX 87.700 mm.

MIN 87.350 mm.

(there are different thicknesses of

shim available to ensure that the

thickness is correct.)

- Next install the selector forks, the

selector drum and the washers, and

the selector fork studs. Lubricate the

surface of the gear mechanism with

AGIP gear 10W40.

- Check that the gearbox operates

correctly, by selecting the different

gears, and turning the selector drum

in both directions. If it seizes, check

once again that the components have

been correctly fitted. Leave the gear-

box with neutral selected, and confirm

that all the elements in the assembly

are able to rotate freely.

- Fit the crankshaft into the right hand

side crankcase half.

- Fit a new crankcase sealing gasket,

paying particular attention to the free

piece in the area of the admission

system.

- Heat up the left hand crankcase half

to approximately 60ºC, and close it

onto the right hand crankcase half.

Then fit the assembly securing studs,

after first ensuring that they are scru-

pulously clean.

- Crankcase joint securing screw tor-

que setting: 6Nm (0,6 mkg).

- Check that the crankshaft and the

gearbox shafts rotate freely after the

crankcase is completely closed.

12-6

2ª 6ª 4ª 3ª 5ª 1ª

Z-30 Z-22 Z-24 Z-27 Z-23 Z-34

- Check the axial play of the gearbox secondary shaft,

which should be between 0.2 and 0.4 mm.

- Using the special installation punch tool (special tool,

part reference number: 00H05400451), fit new seals on

the crankshaft, first applying AGIP Speed lubricant to

the lips.

- Refit the primary drive assembly.

- Refit the magneto - ignition system.

- Refit the cylinder, piston, and cylinder head assemblies.

- Remount the engine into the frame.

- Refill and bleed the cooling system, and the separate

engine lubricating system.

- Refill the gearbox-clutch side crankcase half with oil.

- Start up the engine and carry out a brief check of all its

functions, and check the correct operation of the gear-

box and the clutch.