48 Ferm

If all preparations have been done the machine can be

connected to the mains by putting the plug into the power

point. Beforehand check if the mains switch is “OFF” and

check if the turning directions is “RIGHT”. Watch the gau-

ge once more and see if the oil level has not changed and if

necessary you have to fill it till the gauge half-full. See that

there is no paper or cleaning-rag for the ventilati on ope-

nings of the motor. Check the three-jaw and see that the

basins cannot come out of the jaw.

PUT THE JAW-WRENCH ON A PERMANENT

PLACE!

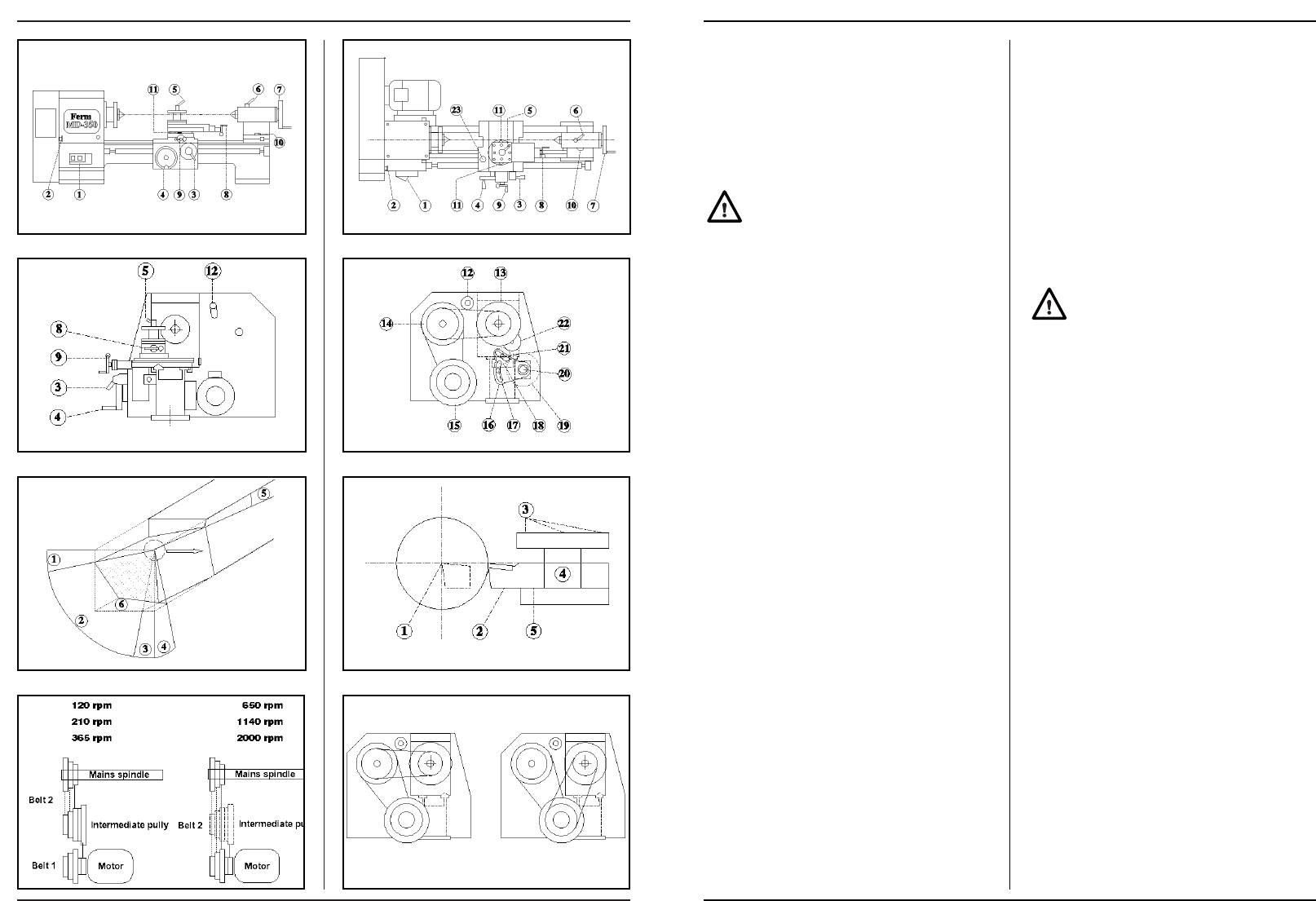

Open the protection case and check the position

and tension of the belts. For running on trial the lowest tur-

ning speed has to be chosen. You may shift the front belt,

watch fig.5 and 15.

Push in the switch and have the machine turned during 20

minutes. Check regularly if the head bearings in the head-

stock and the motor do not become hot by stopping the

machine and putting a hand on both side of the headstock

and on the motor body. Immediately stop if you hear a de-

viating noise and if you feel an abnormal heath develop-

ment( more than handwarm) and first con tact your sup-

plier.

Then switch over to a higher speed and have the machine

also function a few minutes on this speed. Do this again

with a reversed turning direction. If no problems have ari-

sen, the machine is ready for use.

WORKING METHOD

Removing metal takes place by pushing under control a

chisel point or a boring point in the piece of work through

which small pieces of material - chips - are cut away. For

this the piece of work has to make a turning movement be-

tween two fixed turning points- the headstock and the tail

stock (watch fig.1) - which lie on a very precise, imaginary

line: the centerline(4). This can be turned off paral lelly to

the centerline over the whole lenght, by carrying the chisel

which has been fixed on the support(5) in a certain tempo

along the turning piece of work. This has to be done in a

straight line, with the hands or automatically with the trans-

mission(6).

For removing material of the piece of work, power is nee-

ded. This power is transmitted from the motor to an empty

shaft in the headstock: the main shaft (2). In connection

with the maximum motorcapacity the quantity material

which has to be taken - the chip thickness and the width of

chip- has to be adapted. If the number of revolutions lo-

wers too much, the starting depth or the rate of speed has

to be lowered. Otherwise there is a chance of motor dama-

ge, shorter tool life of the chisel or the chisel rupture. The

diameter of the piece of work is also influences this. If you

have a diamter of 100 mm more power is needed for cut-

ting a chip of 1 mm than at a diameter of 10 mm.

When the tail stock (8) is placed next to the centerline be-

cause of cross adjustment, an outward conical plane is tur-

ned. An extra processing possibility over the lenght axle is

cutting a screw-thread. A special chisel cuts a spiral dee-

pening in the outline of the piece of work. A part of the out-

line keeps on standing and this height difference forms the

ultimate screw-thread. Next to turning over the lenght ax-

le, the ends of a piece of work can also be processed, for

example for making them flat and straight. Short pieces of

work can be fixed at one side in a fixed turning-point, the th-

ree-jaw chuck, and on the other side be processed at right

angles to the centerline. The basins of the chuck see to

maintenance of an imaginary centerline. By having occur-

red the chisel replace ment under an angle by adjustment

of the chuck, inward and outward conical planes can be

turned. With this strain borings can also be made in level-

led surfaces. For that a drill chuck has to be bought sepa-

rately. This drill chuck with morse cone peg has to be in-

stalled in the sliding tube (7) of the tail stock. Then the gaps

can be screwn out until the desired depht, diameter and

form.

IMPORTANT:

The precision of the pieces of

work is first and particularly depen dant of ex-

pertness and experience. During turning many

factors can influence the end result, like the sort and the

condition of the chisels, the nature of the material you want

to process, the turn and starting speed, the fixation of the

piece of work, the drafting and the condition of the machi-

ne. With the MD-350 it is possible to manufacture prolon-

ged pieces of work with a big accuracy, if all circumstances

are perfect.

FOR THE BEGINNING TURNER.

During turning big powers on certain parts can be develo-

ped. If you use the machine incorrect these parts can be

damaged or deformed and wear end tear faster, even if

they have been made and designed very expertly and ca-

refully. Through this the accuracy of the machine will de-

crease strongly, which directly influences the quality and

tahe preciseness of your pieces of work. So it is important

that the apparatus is tended in an expert way. Recommen-

ded is, if you are not a skilled turner, to start with simple pie-

ces of work and to try the different possibilities of the lathe

with trial pieces of work. It is instructive to look at skilled tur-

ners, because you are not that fast a perfect turner! For pre

venting disappointments you have to become familiar with

the basic principles of turning. Turning is not for nothing a

profession. You can find referencebooks about metal wor-

king and metal turning in the library or in a book-shop. Bes-

ides model-building magazines write about this subject re-

gularly. The best is getting into possession of a, if need be

obsolete, technical text-book. In this book is told about the

general principles of turning and many things worth kno-

wing and handy summaries of problems with possible

causes and solutions.

FUNCTION OF THE MACHINE.

For a good understanding of the working of the machine

this one can for conve nience sake be divided in a number

of main groups and components, all with a special func-

tion. Watch fig.1.

Ferm 5