68 Ferm

1

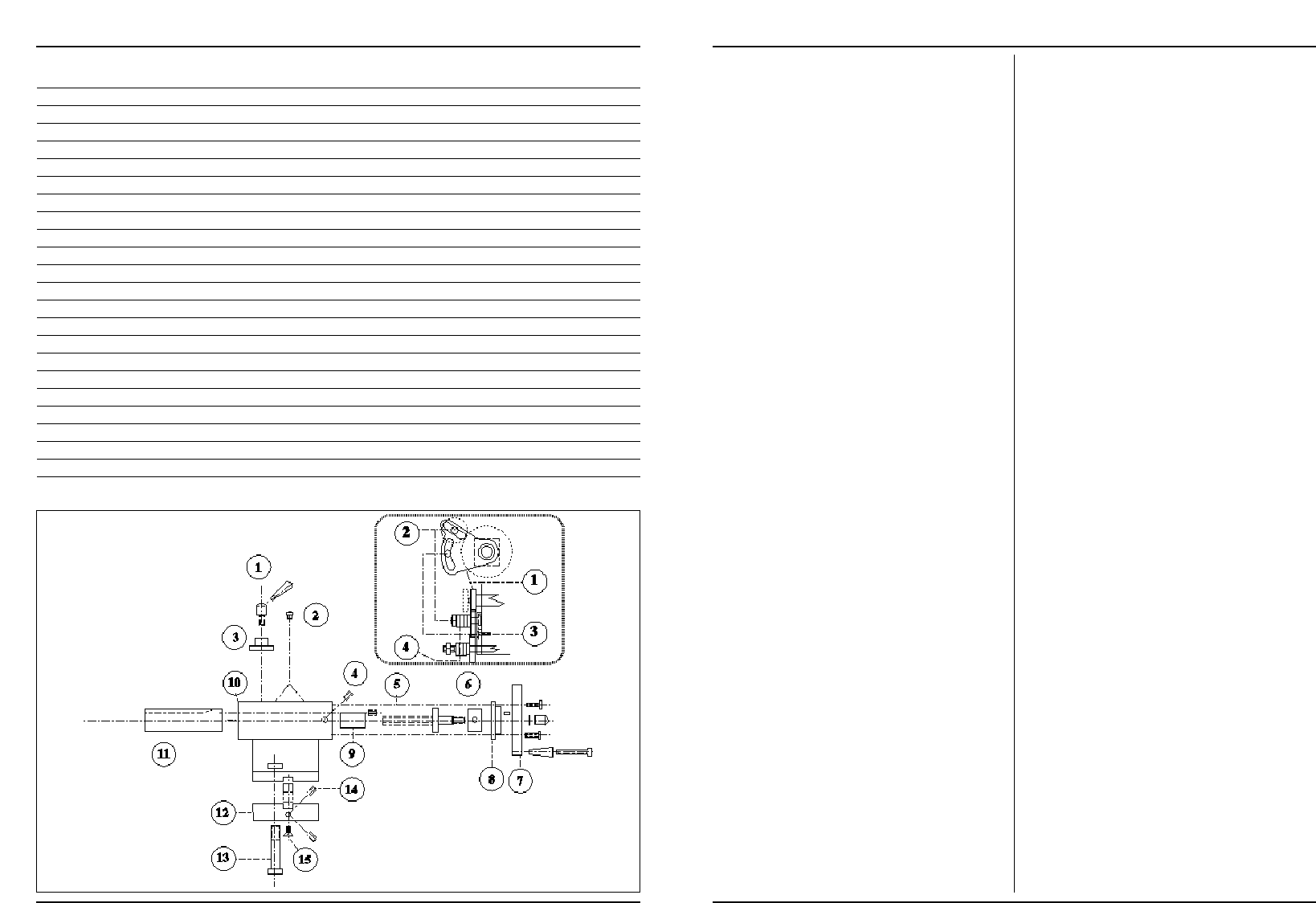

ANNEX 1 - PARTS LIST TAILSTOCK/SHEARS

NR PART

TAILSTOCK

1 CLAMP LEVER

2 BALL NIPPLES

3 CLAMPING NUT

4 LOCKING SCREW

5 SPINDLE

6 SPINDLE BEARING

7 HANDWHEEL

8 COVER PLATE

9 SPINDLE NUT

10 TAILSTOCK

11 SLIDING BUSH

12 BED

13 CLAMPING BOLT

14 ADJUSTING SCREWS

15 NUT

SHEARS

1 SHEARS

2 IDLER SHAFT

3 LOCKING BOLT

4 SPACING RING

THE TAIL STOCK

Fig.1

The end of the centerline is formed by the tail stock (8).

The axis of the fixed and tail stock are exactly in each

others extension. Depending on the lenght of the piece

of work the head can be moved over the bed and it can

be fixed. With the slide bush (7), in which a center has to

be installed, the piece of work can be exerted fixed and

revolving right on the centerline. If you turn back the

slide bush, the center is automatically untied. The body

of the head has been divided. The upper part can be

adjusted sideways with regard to the upper part by

means of adjusting screws. Through this an adjustment

next to the centerline can be obtained. Normal

movements in the lenght direction do not have side ways

adjustments as a consequence.

THE COMBINED

TRANSMISSION/STARTING AXLE

Fig.3 & 4

For a good surface quality a correct and particularly a

constant rate of turnover in the longitudinal direction is

important. For longer pieces of work this is almost

impossible with your hands. By closing the lock nut the

support is coupled with the thread on the transmission.

When the transmission has been switched on this one

has been coupled to the main shaft in his turn. With this a

coupling is made with an intermediate wheel between

the drive wheel of the transmission and the drive wheel

for the longitudinal feed on the headstock. This happens

because of an adjustment of the change wheel scissors,

watch fig. 3 and 4.

At each rotation of the main shaft the support will move

itself over a certain distance along the bed. This distance

depends on the wire haste and the chosen wheel change

on the transmission. By chosing another wheel change

the star ting speed can be adapted.

With thread-cutting the same happens in principle,

however with a much bigger support movement with a

much lower main shaft speed. In this case a coupling has

to be made with the thread-cutting driving gear of the

headstock. The positioning of the gear wheels happens

by the installation of the rings on the starting axle and

intermediate wheel axle of the scissors. In this case

change of the change wheel on the transmission makes

possible a choice of the haste of the thread which has to

be cut. On the transmission is no automatic cut out. So

switch this one off for preventing that the chisel runs

against the chuck.

THE DRIVE

Fig.5

Since the applied motor has a fixed and relatively high

number of revolutions the transmission has been done in

such a way that this reduces the numbers of revolutions

at the same time. Besides, with the application of plural

pulleys and an intermediate pulley this number of

revolutions is variable in six successive steps.

For lifting up possible belt tension differences the

bearing-mounted belt pressure roll has been made

variable. Watch fig.5. For reaching the three highest

spindle speeds the front belt has to be shifted from the

intermediate-pulley to the motor pulley. The

intermediate gear keeps driven and serves as flywheel

for catching load variations.

BASIC PRINCIPLES OF THE TURNING

Before you can start turning, you have to know the most

important basic under standings. Otherwise there is a

change that the wrong turning speed or the wrong chisel

is chosen. With a number of tables and rules making the

machine ready for turning is easier.

CLAMPING

Fig.6 - 8

Clamping the piece of work has to happen with care. Put

the piece of work in the chuck as far as possible and

clamp this one with the tightening wrench. If you clamp

too hard the chuck, basins or the piece of work can be

damaged. The same applies for the sliding tube. Tighten

this one with your hands, strong but not by force. Some

clamping examples by which also the use of bores and

chisel is made clear, can be seen in fig.6, 7 and 8.

The represented standard three-chuck is self-centring.

Through this the axis of a small piece of work falls exactly

on the centerline, even if the dead centre is not used.

With a chuck belongs an inside basin (represented) and

an outside basin. These ones are used for inside clamping

of bigger diameters. Every basin has in the chuck the

same place. Place and basin are numbered!

In fig.6 a right side cutting chisel (up) and a right bended

roughing tool is used. The arrows indicate the starting

direction. The roughing tool can be used in longitudinal

direction and in cross direction and is often used for

quickly elimina ting many material. Fig 7. shows the use of

a left side cutting chisel (up) and a blind boring chisel.

Fig.8 shows a clamp with dead center in a tail stock. A

pointed chisel has been used for an egal finish. Under this

figure a clamping is represen ted for making a bore with a

spiral drill. Beforehand you have to pre-drill with a

center bore. This is a bore from which the shank is much

thicker than the crossing frog. The boring gap which

arises through that serves as a center gap for both the

center and the bore!

Ferm 9