4.5. Cleaning the heatin

It is

for

advise the requirement technicians will install y

Further, approach in the

By regular cleaning of

the performance of the heating system and guarantee a trouble-free function and operation. By

regular

walling.

4.6 Fire in the chim

In

fuel

the fire brigade imm

4.7.

External combustion air suppl

For

15

3

result in low airiness coefficient, due to plastic windows, etc.). Another i may be exhaust

devices

installed. In

with tarring and

that

room. It is more convenient if you – along with the i of the heating device – install a

ventilation

clogging). It

the procedure TPG 704 01 “G

buildings“.

4.8. External air supply

Modern

is supplied for making the firing process perfect, especially in case of houses with lo airiness

coefficient (well insulated from external environme due to construct elements r

natural circulation (plast windows, doors etc.). additional supply be

connected

chimney system made by SCHIDEL. Another opt a connection with space where the air

circulation

solution for particular house should be suggested by the chimney company the

company responsible for t

5. OPERATING INSTRUC

5.1. Before first operati

If the fireplace insert is supplie

Before the first putting into operation, y

the ashpan or inside the hearth, including transport clamps etc. Following the illustration in the

Technical Card, check

shapes or barrier are located properly (they have moved out of the position during

transportation

device might not w

When the fireplace insert has been positioned and connected to the chimney system, make (not very

big) fire, maintaining it for

As soon as the devi

If the complete fireplace set

Following the inst for installation, place and connect the fireplace insert t the chimney

system

After

the hearth

fire for at least one hour.

The

in

damage

should be very small, to “warm up” the device gradually: it is recommended to load smaller quantities

to establish lower temperature. All materials ne

used to” the thermal stress. By such slow heating up, y avoid cracks in fireclay bricks, likely

damage on surface paint or material deformation in general. Th

hardening process at the first putting into operation is just temporary – how

recommended

for a while.

With

gaps (which may

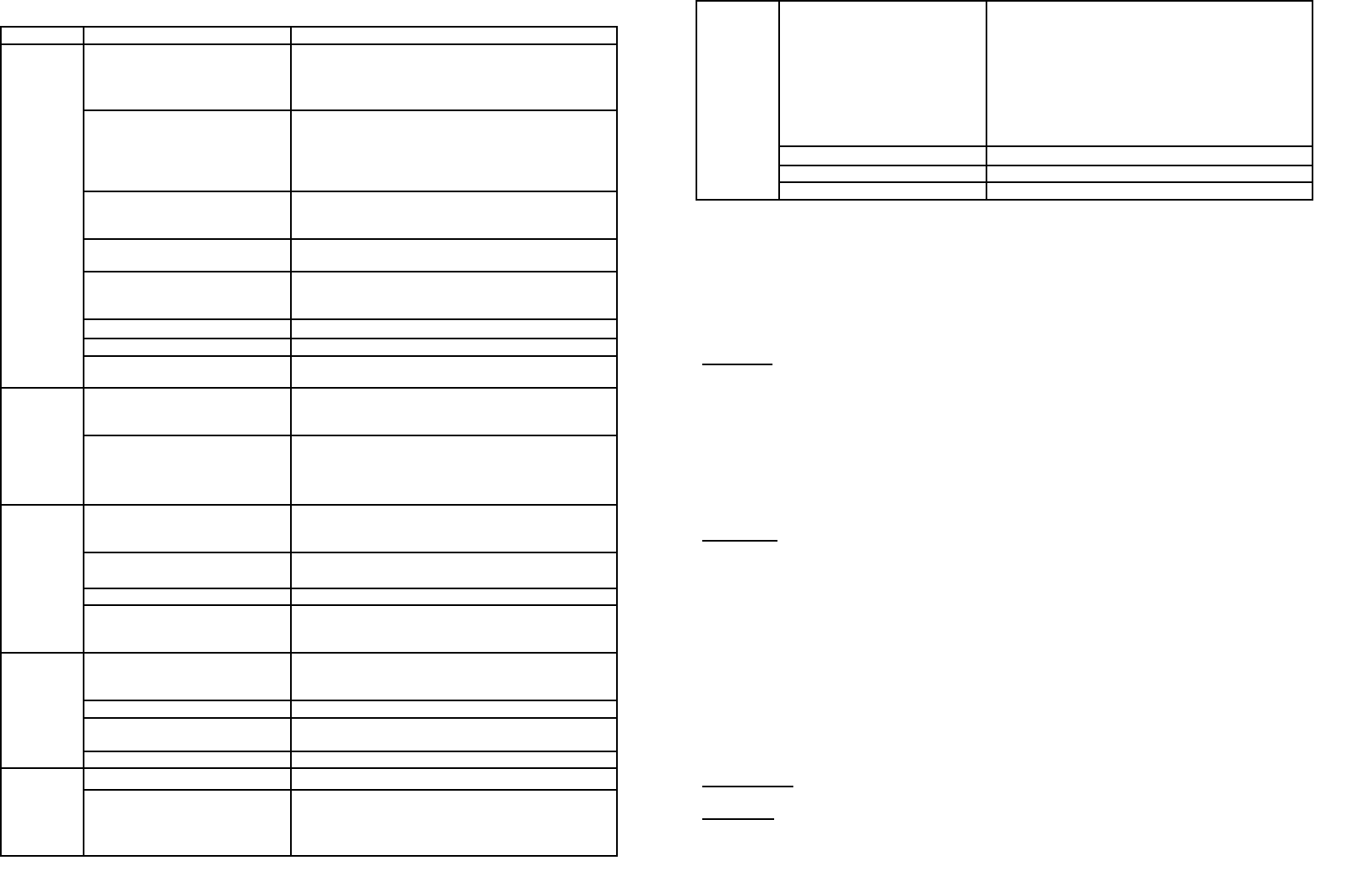

What to do if you find a gap bet Partially release the holder nuts.

the segment to the edges touch slightly and

carefully, tighten up the

5.2. Setting the fire

To set the fire easily, follow this

grate.

layer). You should always load a bigger quantity (i.e. enough wood , which means

of

long

Open

supply

shut all the time. As soon as the wood flares up properly, use the air supply regulators to set not very

intensive,

specified in the Technica

You may poke the fire

Caution! The stoking door (the firing chamber) and the ashpan door (if installed with your

particular model) must be ,

Caution! After e before check the

insert for clearness and cl

5.3. Feeding the fir

To prevent the smoke spreading through

recommended: to 10 before y the open the

regulator

smoke exhausting through the chimney. After that,

time

door. When the burns (no black , the regulating system ba in the

previous

does

fuel

hourly

overload the stove w

Caution!

feeding, reload the

9 10