11

First Operation

2.5 Operation

1. Switch on the machine.

2. Use lever (Fig. 5/3) to lower squee-

gee. Suction turbine switches on au-

tomatically.

3. Switch on clear water supply by me-

ans of tip-switch (Fig. 4/14).

4. Adjust clear water amount by means

of tip-switch (Fig. 4/13).

5. Use pedal (Fig. 5/9) to lower brush

head.

6. Use accelerator lever (Fig. 5/1) to

adjust work speed and direction.

Increases the plate brush pressure if

required with pedal (Fig. 5/10) .

Start moving machine imme-

diately after lowering of the

brush head, otherwise the

brushes leave traces on the

floor. Lift-out squeegee before

changing to reverse ride and

lift-out brush head before pas-

sing over dormers and more.

2.6 Stop Machine

If release the accelerator lever, this re-

turns automatically into the neutral posi-

tion. The machine stops. Protect the

machine against unintentional move-

ments or against being inadvertently

started.

2.7 After Work

1. Ride machine to suitable site for

maintenance.

2. Stop machine, lift squeegee and

brush head and pull key switch.

3. Empty and clean soiled water tank.

Observe the legal directives

and local regulations for dispo-

sal of detergents, see Water

Management Act.

4. Check clear water filter.

5. Check seals and suction hose.

6. Check operating media levels,

function and setting.

7. Charge batteries.

8. Clean the machine.

Empty the clear water tank before

shutting down the machine for a longer

time.

Do not clean the electrical

parts by means of high-pressu-

re cleaning equipment.

2.8 Transport rides

For transport rides to the place of use of

the machine, switch it on, lift-out squee-

gee and brush head and actuate the ac-

celerator switch according to the

desired direction of travel.

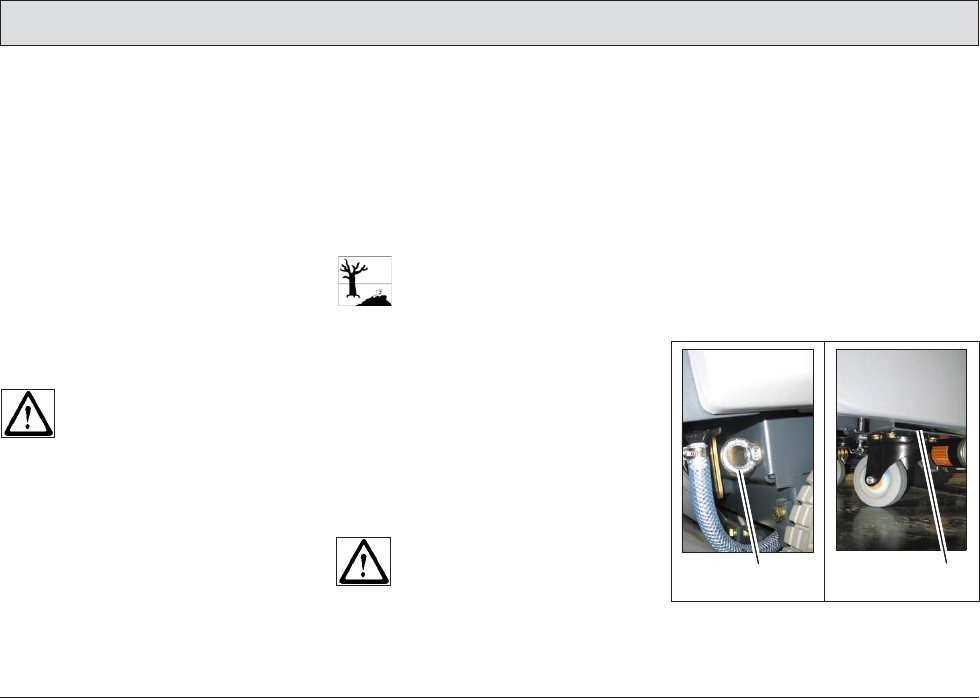

2.9 Tie-down points

In case of transport on a vehicle or trai-

ler, the machine has to be protected

against rolling off. Tie the machine

down firmly by lashing it to the front with

the eye bolts (Fig. 2/1) and to the rear

with the chassis (Fig. 2/2) .

Fig.2

1

2

11

First Operation

2.5 Operation

1. Switch on the machine.

2. Use lever (Fig. 5/3) to lower squee-

gee. Suction turbine switches on au-

tomatically.

3. Switch on clear water supply by me-

ans of tip-switch (Fig. 4/14).

4. Adjust clear water amount by means

of tip-switch (Fig. 4/13).

5. Use pedal (Fig. 5/9) to lower brush

head.

6. Use accelerator lever (Fig. 5/1) to

adjust work speed and direction.

Increases the plate brush pressure if

required with pedal (Fig. 5/10) .

Start moving machine imme-

diately after lowering of the

brush head, otherwise the

brushes leave traces on the

floor. Lift-out squeegee before

changing to reverse ride and

lift-out brush head before pas-

sing over dormers and more.

2.6 Stop Machine

If release the accelerator lever, this re-

turns automatically into the neutral posi-

tion. The machine stops. Protect the

machine against unintentional move-

ments or against being inadvertently

started.

2.7 After Work

1. Ride machine to suitable site for

maintenance.

2. Stop machine, lift squeegee and

brush head and pull key switch.

3. Empty and clean soiled water tank.

Observe the legal directives

and local regulations for dispo-

sal of detergents, see Water

Management Act.

4. Check clear water filter.

5. Check seals and suction hose.

6. Check operating media levels,

function and setting.

7. Charge batteries.

8. Clean the machine.

Empty the clear water tank before

shutting down the machine for a longer

time.

Do not clean the electrical

parts by means of high-pressu-

re cleaning equipment.

2.8 Transport rides

For transport rides to the place of use of

the machine, switch it on, lift-out squee-

gee and brush head and actuate the ac-

celerator switch according to the

desired direction of travel.

2.9 Tie-down points

In case of transport on a vehicle or trai-

ler, the machine has to be protected

against rolling off. Tie the machine

down firmly by lashing it to the front with

the eye bolts (Fig. 2/1) and to the rear

with the chassis (Fig. 2/2) .

Fig.2

1

2