ENGLISHen

16

– Lock the turn table in the desired position.

– Swivel arm inclined at desired angle to the

workpiece surface and locked.

– Pulling device at the very rear.

–S (18) of the pulling device has been

loosened.

– Set workpiece stop (30:

Release lockin31). Slide the

workpiece stop (30) (upper and lower part)

such that it supports the workpiec

possible without touching the blade or

protective cover. Fasten with lockin

(31).

For certain angle po

to remove the right-hand, movable u

the workpiece stop (30) entirely, after loosening

the lock screw (31) . Retighten locking scre

(31). (After the saw cut,

and fasten with locking screw (31so that it is

not lost.)

– Only KGSV 72 Xact SYM: Align parallel guides/

ripping fences (30) flush (in on

locking levers (32) all the way downwards.

Cutting the workpiece:

Danger!

With a double mitre cut, the saw blade is easier

accessible due to th

results in a higher risk of injury. Always keep

sufficient distance to the saw blade!

Cut the workpiece, as described f

cuts".

9.5 Cutting grooves

Note:

The cutting depth limitation together with the

pulling device permits

does not result in a

of a certain depth is effected in the workpiece.

Risk of kickback!

When cutting gr

that no lateral pressure is exerted on the

blade. Otherwise, the saw head might

kick back! Use a clamping device when cutting

grooves. Avoid lateral pressure on the saw head.

Starting position:

–T (16) pulled out.

–S

– Swivel arm inclined at desired angle to the

workpiece surface and locked.

– Lock the turn table in the desired position.

– Pulling device at the very rear.

–S (18) of the pulling device has been

loosened.

Cutting the workpiece:

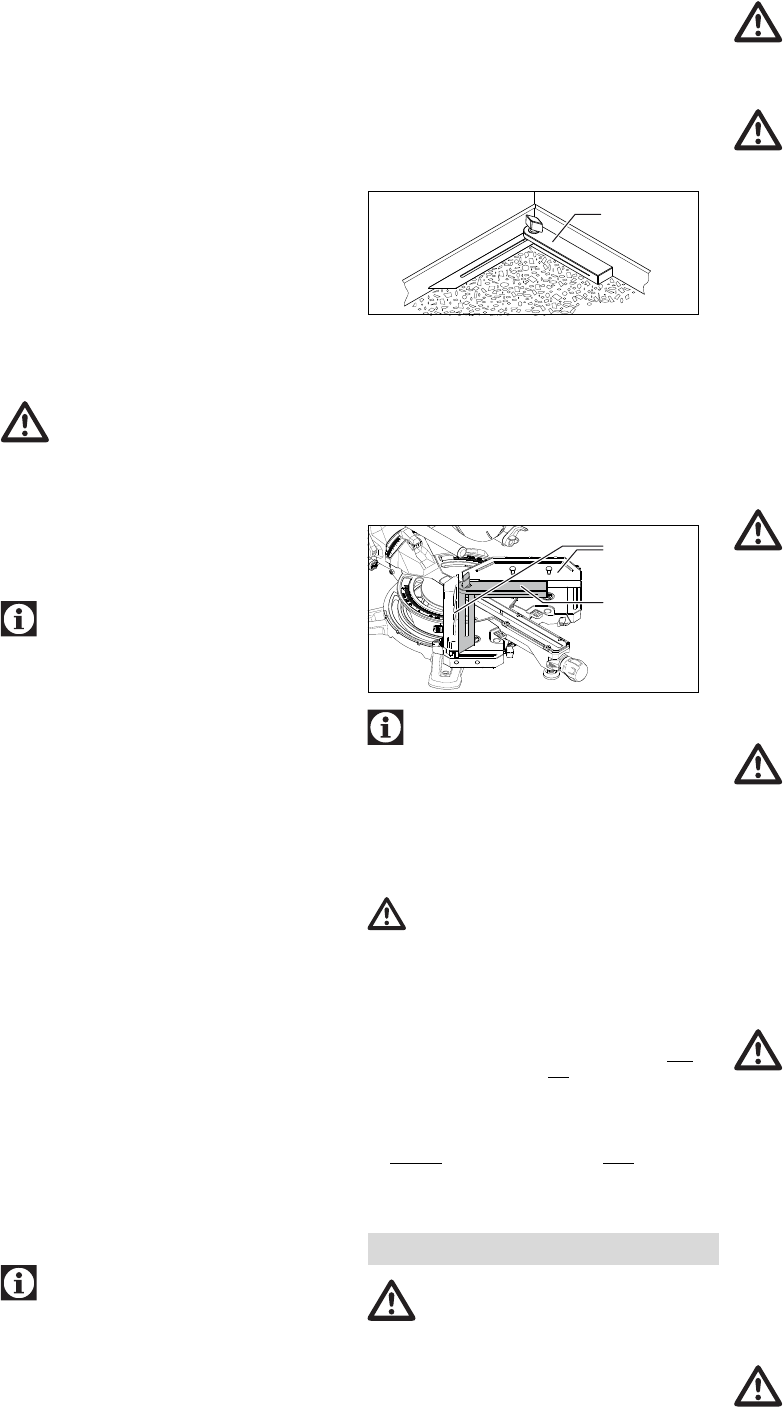

1. Set the cutting depth limitation (47) to the

desired cutting depth

2. Loosen safety lock (29) and swivel sa

downwards to chece set cutting depth:

3. Effect trial cut.

4. If required, repeat steps 1 and 3 until the

desired cutting depth has been set.

5. Cut the workpiece, as described for "Straight

cuts".

9.6 Only KGSV 72 Xact SYM:

Symmetrical cuts

Note:

For fast and easy sawing of mitre cuts with

symmetrically adjustable g

Starting position:

–T (16) pulled out.

–S

– Cutting depth limitation (48) deactivated.

– Turntable is in 0° position, l

(22) for turntable

– Inclination of the saw h

normally 0°. The saw head can also be inclined

for special cuts. The locking lever (14) for

setting the angle of inclination is tightened.

– T

position using (18).

– Make sure the adjustable parallel

fence (30) is set correctly to support the

workpiece and will not interfere with the blade or

the guard. Fix bo

fences (30) with set screws (31) .

Adjusting the angle:

1. Place the supplied “adjustable angle” (34) at

the original angle (e.g. the corner of the room).

Transfer the original angle to the “adjustable

angle” (34) .

2. Pull both locking levers (32) upwards and

loosen the clamping mechanism.

3. Push the safety catches (33) all the way

downwards toactivate the locking function.

4. Place the “adjustable angle” (34) on the

turntable (23)

5. Transfer the angle of the “adjustable angle”

(34) to the guide syst

of the table (9) / parallel guides/ripping fences

(30) at the same time and place at the

“adjustable angle” (34) .

Note:

If the safety catches (33) are in their top position,

the two halves of the table (9) / parallel guides/

ripping fences (30) lock at the angle levels of 45°,

22.5°, 0°, -22.5° and -45

(33) are pressed downwards the locking function

is deactivated.

6. Press both locking levers (32) all the way

downwards to

Danger!

Both lockin

(32) must be pushed

downward

the angle cannot change during the sawing

process.

Cutting the wo

7. If required, push the opposite parallel gu

ripping fenc (30) to the side. Push the first

workpiece against the left parallel guide/

ripping fencewith wo

(11) and saw as described in “Straight cuts”.

8. If required, push the opposite parallel gu

ripping fenc (30) to the side. Push the

second

workpiece against the right parallel

guide/ripping fence and fix with workpiece

clamps (11) and saw as described in “Straight

cuts”.

Danger!

Disconnect from the mains power before any

maintenance or c

– Repair and maintenance work other than

described in this section sh

out by qualified

– Replace damaged par

installation

approved by the equipm

cause unforeseeable damage.

– Check that all safety devices are operational

again after

10.1 Saw blade

Risk of burning!

Directly after cutting the saw blade can be very

hot. Let a hot saw blade cool down. Do not clean

the hot saw blade with combustible liquids.

Risk of injury, even with the blade at

standstill!

When loosening

screw (40) the (7) has to

be swivelled over the saw blade. Wear gloves

when changing blades.

1. Disconnect the mains pl

2. Put the saw head in the upper position.

3. Lock saw blade: press the locking button and

turn the saw blade with the other hand until the

locking button enga

locking button.

4. Remove the tens

(40) on the saw blade shaft with

(17) in clockwise direction (left-h

5. Loosen safety lock (29) and push the

retractable blade guard (7) upwards and hold.

6. Carefully remove outer flange (41) and saw

blade (42) from the saw blade shaft and close

again the retractable blade guard.

Danger!

Do not use cleani

residue) that could corrode the light metal

components of the saw; the

would be adversely affected.

7. Cleaning the clamping surfaces:

– Saw blade shaft (45) ,

– saw blade (42) ,

–o (41),

– i (44) .

Danger!

Place inner flange properly! If this is not the case,

the saw can block or the saw blade coul

loose. The inner flange isin the correct position if

the ring grootowards the saw blade and

the flat side to the motor.

8. Put on inner flange (44) .

9. Loosen safety lock (29) and push the

retractable blade guard (7) upwards and hold.

10.Put on a new saw blade - observe direction

rotation: Seen from the left (open) side, the

arrow on thhas to correspond to

the direction of the arrow (43) on the saw

blade cover!

Danger!

Use only saw blades, which fulfil the requirements

and specificationsed in these operating

instructions.

Use only saw blades designed for the maximum

speed (see "Technical Specificat

unsuitable or damaged saw blades parts

used, parts can be ejected due to centrifugal

force in an explosive-type manner.

Saw blades intended for c

materials have to conform to EN 847-1.

Do not use:

– saw blades made of high-alloy speed steel

(HSS);

– damaged saw blades;

– cut-off wheel blades.

Danger!

– Mount saw blade using

– Do not use loose-fittireducin

blade could work loose.

– Saw blades h

that they do not wobble or run out of balanc

and cannot work loose during

11.C (7).

10. Care And Maintenance