13

Electrical connection

Before connecting the appliance to the

power supply, always follow the instructions

and warnings in the chapter entitled ”Safety

instructions”!

The extractor hood may only be

connected by a qualied electrician who is

familiar with the regulations of the relevant

electricity supply company.

ṇ RISK OF INJURY

If the power cord of the extractor hood is

damaged, it must be replaced by the

manufacturer, his customer service or

a similarly qualied person to prevent

hazardous situations.

The power cord must be stowed away

securely following connection to the mains.

The extractor hood may be connected to

a correctly installed earthed socket only.

Attach the earthed socket as directly as

possible behind the ue duct.

– The earthed socket should be connected via

its own circuit.

– If the earthed socket is no longer

accessible following installation of the

extractor hood, a disconnector must be

tted as for a permanent connection.

If a permanent connection is required

A disconnector must be provided on the

installation side. Switches with a contact

opening of more than 3 mm and all-pole

disconnection are regarded as

disconnectors. This includes LS switches,

fuses and contactors.

Electrical specications

The required connection data can be found

on the rating plate inside the appliance

when the grease lters have been removed.

Length of the power cord: approx. 1.30 m

This extractor hood complies with the EC

interference suppression regulations.

Installation

Prior to installation, always follow the

instructions and warnings in the chapter

entitled “Safety instructions”.

The extractor hood is designed to be

mounted on the wall.

During installation, optional accessories may

also require tting.

Observe the minimum distance between

hob and extractor hood (see “Safety

instructions”)!

Avoid damaging the sensitive surfaces!

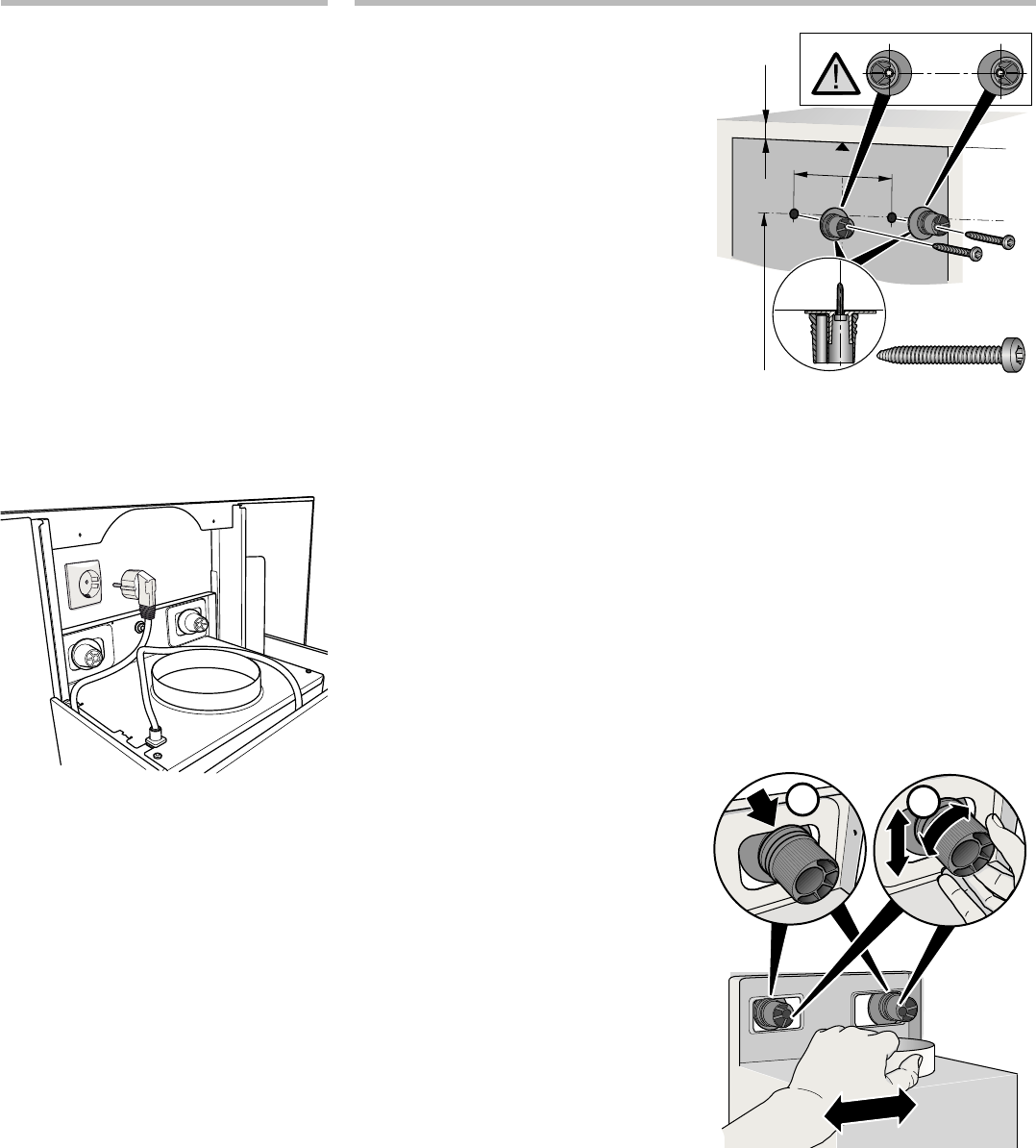

Preparing the wall

ṇ RISK OF INJURY,

DAMAGE TO PROPERTY

Before drilling the holes for the designated

installation location, check for concealed

electrical cables and other lines.

The wall must be level and vertical.

The enclosed screws and wall plugs are

suitable for solid brickwork. Use the appropriate

xing materials for other wall structures

(e.g. plaster board, porous concrete, poroton

bricks).

Ensure that the wall has adequate load

bearing capacity.

Ensure that the depth of the drilled holes

corresponds with the length of the screws.

Ensure that the wall plugs are secure.

Max. weight in kg: 55

Design subject to modication in line with

technical development.

Installation preparations

1. Using the enclosed template, mark positions

for the screws and, to facilitate attachment,

the contour of the attachment area. The

lower edge of the template corresponds to

the lower edge of the extractor hood.

2. Drill 2x 8 mm Ø holes for suspension of the

extractor hood and press in wall plugs ush

with the wall.

.

3. Screw on the brackets for the extractor

hood: hand tight, max. 3 Nm

Ensure that the washers and brackets are

positioned correctly!

Attachment and alignment

1. Mount the extractor hood, ensuring

that the back is attached firmly to the

brackets Ⓐ.

2. Align the extractor hood horizontally by

turning the brackets.

If required, the extractor hood can be

moved to the right or left

Ⓑ.