ATTENTION:

All repairs must only be carried out by a specialised technician, with the product switched o and the plug

disconnected.

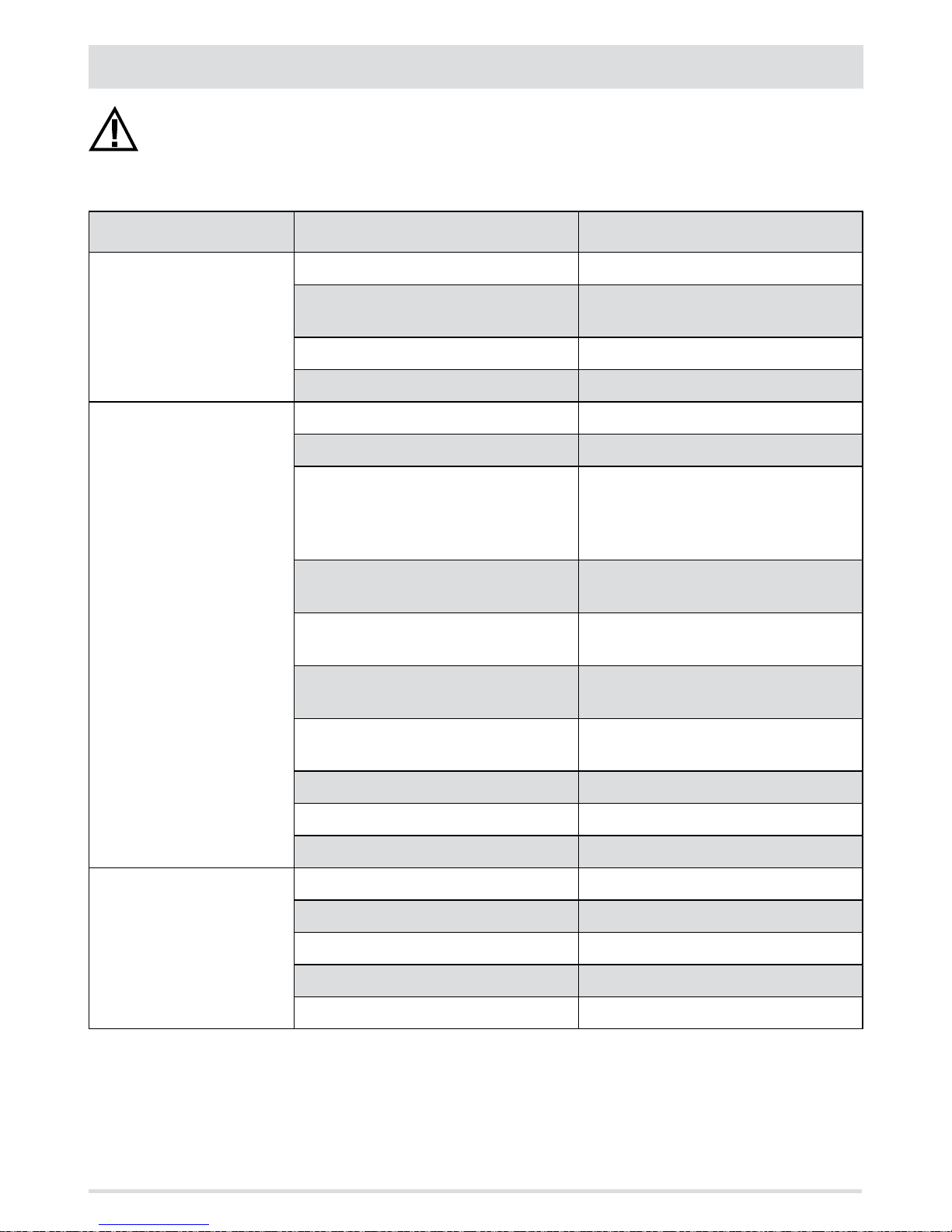

ANOMALY POSSIBLE CAUSES SOLUTIONS

The pellets are not fed into

the combustion chamber.

The pellet hopper is empty Fill the hopper with pellets.

Sawdust has blocked the feed screw Empty the hopper and remove the sawdust

from the feed screw by hand.

Faulty gear motor Replace the gear motor.

Faulty electronic board Replace the circuit board.

The re goes out or the boiler

stops automatically.

The pellet hopper is empty Fill the hopper with pellets.

The pellets are not fed See the previous anomaly.

The pellet temperature safety probe has been

triggered

Let the product cool down, restore the

thermostat until the lockout is o and switch

the product back on. If the problem persists,

contact Technical Assistance.

The door is not closed properly or the gaskets

are worn

Close the door and replace the gaskets with

original ones.

Unsuitable pellets Change the type of pellets with those

recommended by the manufacturer.

Low pellet supply Check the ow of fuel following the instructions

in the manual.

The combustion chamber is dirty Clean the combustion chamber, following the

instructions in the manual.

Clogged outlet Clean the smoke duct.

Faulty smoke extraction motor Check the motor and replace it, if necessary.

Pressure switch broken or defective. Replace the pressure switch.

The product works for a few

minutes and then switches

o.

Start-up phase is not completed Repeat start-up.

Temporary power cut Wait for the automatic restart.

Clogged smoke duct Clean smoke duct.

Faulty or malfunctioning temperature probes Check and replace the probes.

Faulty spark plug Check the spark plug and replace it, if necessary.