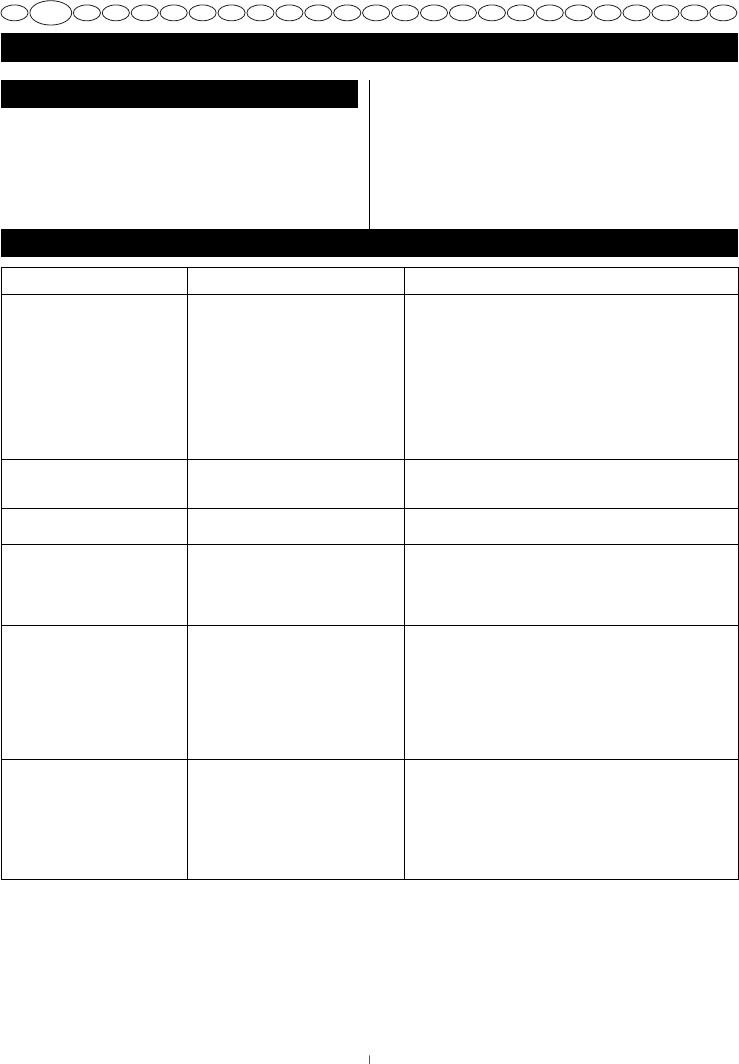

Engine fails to start.

Engine hard to start.

Engine lacks power.

Detergent fails to mix with

spray.

Pump doesn’t produce

pressure.

Machine doesn’t reach high

pressure.

1. No fuel in tank.

2. Spark plug shorted or fouled.

3. Spark plug is broken (cracked

porcelain or electrodes

broken).

4. Ignition lead wire shorted,

broken, or disconnected from

spark plug.

5. Ignition inoperative.

1. Water in petrol.

2. Weak spark at spark plug.

Dirty air filter.

1. Detergent injection hose is not

properly submerged.

2. High pressure nozzle

attached.

1. Low pressure nozzle installed.

2. Inadequate water supply.

3. Spray wand leaks.

4. Nozzle is clogged.

5. Pump is faulty.

6. Air in line.

1. Diameter of garden hose is

too small pressure.

2. Water supply is restricted.

3. Not enough inlet water.

4. Wrong nozzle is attached.

1. Fill tank.

2. Replace spark plug.

3. Replace spark plug.

4. Replace lead wire or attach to spark plug.

5. Contact authorized service center.

1. Drain entire system and refill with fresh fuel.

2. Contact authorized service center.

Clean or replace air filter.

1. Insert injection hose into detergent storage

bucket.

2. Use low pressure nozzle (black) to apply

detergent.

1. Replace with high pressure nozzle.

2. Provide adequate water flow.

3. Check connections and / or replace wand.

4. Clean nozzle.

5. Contact authorized service center.

6. Squeeze trigger on spray wand to remove air

from line.

1. Replace with 19 mm garden hose with Hozelock

style fitting.

2. Check garden hose for kinks, leaks, and

blockages.

3. Open water source full force.

4. Attach the high pressure nozzle.

MAINTENANCE

PREPARING FOR USE AFTER STORAGE

■ Pull the recoil starter grip three or four times to clean

oil from the combustion chamber.

■ Remove spark plug from the cylinder. Wipe oil from

the spark plug and return it to the cylinder.

■ Reconnect the spark plug wire.

■ Refuel the machine as described earlier in the

operator’s manual.

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION