1

DESCRIPTION

This pumping station is (manufactured in a factory

which is quality) certified to ISO 9001. Installed and

used correctly

reliable service.

This device is not designed for persons (in-

cluding children) with limited phy

or mental abilities, or those with minimal expe-

rience and knowledge, unless they are moni-

tored and are giv

for using the device

responsible for their safety

make sure they do not play with the de

2

APPLICA

SANICUBIC® 1 and SANICUBIC® 1

stations specially developed for individual use (de-

tached house or small commercial premises).

SANICUBIC® 2 Classic and SANICUBIC® 2 Pro ar

pumping stations specially developed for indivi-

dual, commercial and small c

buildings, shops, public places).

SANICUBIC® 2 XL is a pumping station specially de-

signed for community use (prof

restaurants, industries

centres).

These devices comply with the EN 12050-1 stan-

dard (pumping station for wast-

ning faeces) as well as the Eur

construction products, electrical safety and elec-

tromagnetic compatibility

3

INST

The SANICUBIC® must be installed in compliance

with standard EN12056-4.

commissioned and maintained by a qualified pro-

fessional specialist.

1- Attention: the space in which the SANICUBIC®

is to be installed must be large enough to leav

least 600 mm of working room around and above

the unit to facilitate such maintenanc

be required.

There must be sufficient lighting

sufficiently well ventila

freezing.

2-Isolating valv

on waste inlets (especially the 110mm inlets)

and on the discharge to ensure that an

maintenance ma

3-

all back flow from the drainage syst

examples in drawing). Back flow can be av

by installing an anti-back flow riser reaching a high

point above the maximum back flow lev

Comment: In the absence of local information to

the contrary, the maximum back flo-

ponds to street level (r

Continue the discharge pipew

backflow riser

4- If the SANICUBIC® is installed in a space such as

a pit for example, w

of a bilge pump in case of flooding.

5-

vent outlet at roof lev-

tance vale as the pump will not function correctly

ELECTRICAL CONNECTIONS

1-

out by a qualified electrician.

The electrical installation must comply with the

standards in for

2-

unit must be connected via an earthed connec

box.

by a high-sensitivity 30 mA differential cir-

ker set at 20 A.

to power the SANICUBIC®. If the pow

unit is damaged, it must be replaced b-

facturer or its after-sales service to avoid all danger

5

OPERA

- SANICUBIC® 1/SANICUBIC® 1®

pump equipped with a high performance shred-

ding system.

- SANICUBIC® 2 Classic/SANICUBIC® 2 Pro c

two independent pumps. Each of these pumps is

equipped with a high performance shredding system.

Both pumps operate alternately to ensur

ware. In case of surchar

run simultaneously (or if one pump fails, the other

takes over).

- SANICUBIC® 2 XL contains two independent

pumps, each with a clearance of 55 mm.

The tank is equipped with three dip tubes, two of

which control motor activation f

and the third controls the alarm sy

• 2 Long dip tubes

During normal operation, as soon as the effluents

reach the long tube

the pumping system switches on.

• Short dip tube

During surcharge operation, if the effluents r

the highest level in the tank (short tube), an au-

dible and visual alarm system is activated and the

pumping system switches on (if it is not faulty).

UK

4

C

1- Once the plumbing and electrical connections

have been made,

are watertight by letting water flo

through each inlet used. Make sure that

is operating correctly by carrying out at least two

start c

2 - -

ly (using the key pad) where no wat-

red the SANICUBIC®. Operation without wa

damages the maceration sy

6

C

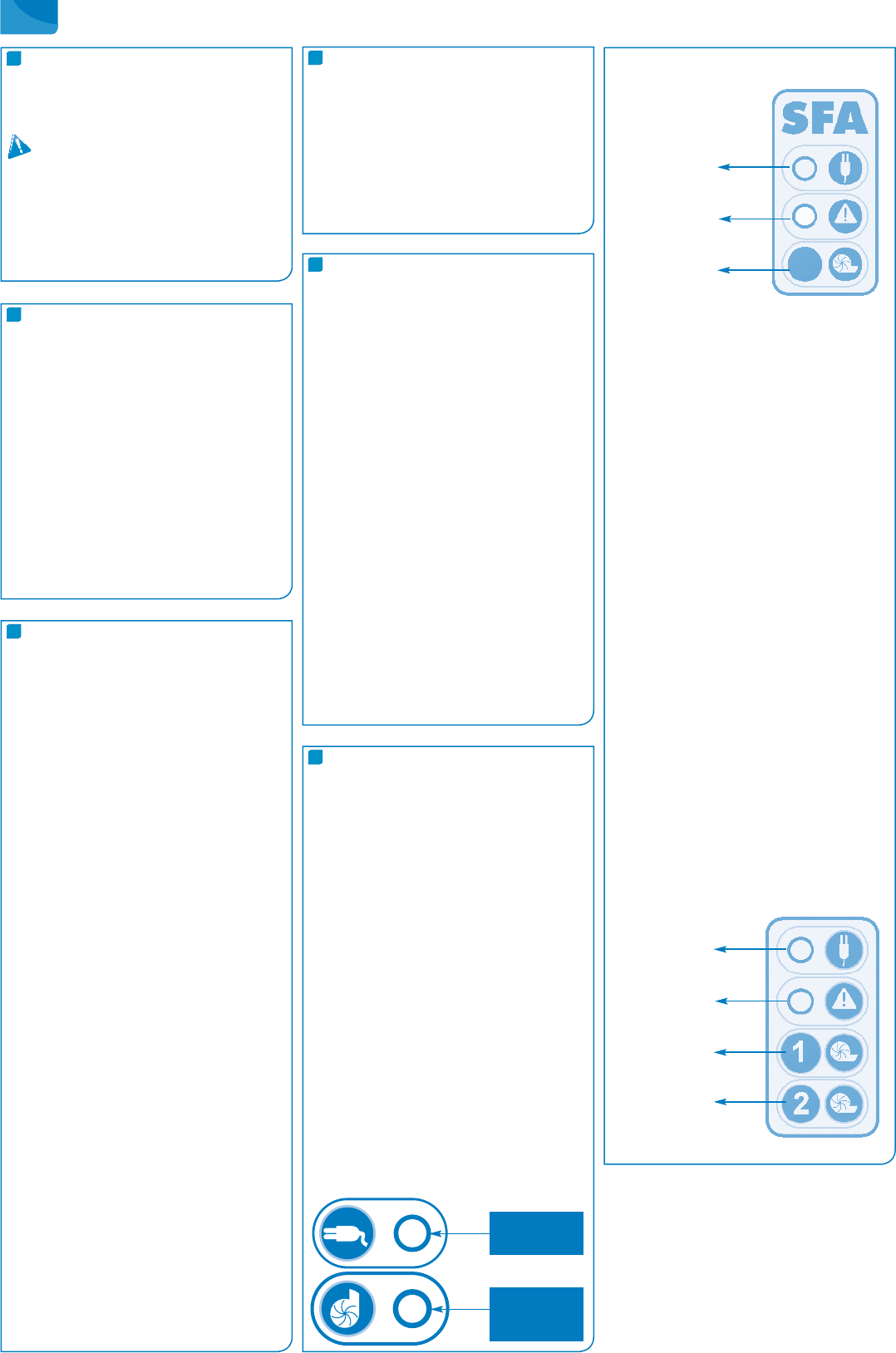

SANICUBIC® 1 CONTROL KEYP

1/ General alarms:

Level alarm:

If the water level inside the device is abnormally

high, the high level diptube microswitch will acti-

vate the motor and the alarm LED lights up red

this LED flashes red, it indicates a det-

blem for the normal water lev

Time alarm:

If the motor runs continuously for more than 1

minute, the red LED alarm lights up

2/ Reset alarm:

The button on the keypad will only allow y

turn off the red LED (it will turn green) if the pro-

blem that triggered the alarm has been resolved

It also allows you to stop the buzzing from the

remote alarm contr

Mains alarm:

- If the LED is off, ther

-

LED flashes green, this indicates that the mains v-

tage has temporarily disappeared.

OPERA

CONTR

OPERA

1/ General alarms:

Level alarm:

If the water level inside the device is abnormally

high: the buzzer is triggered + the red alarm LED

lights up + the motor starts-up. If this LED flashes

red, it indicates a det

water level (L

T

If the motor runs for more than 1 minute: the buz-

zer is triggered + the red alarm LED lights up

Mains alarm:

In case of power failure (or when unplugging the

device): the buzzer is triggered + the red alarm LED

lights up + the yellow mains LED flashes

2/ General alarm reset:

If the problem that triggered an alarm above di-

sappears, the buzzer stops

remains lit as a reminder of the fact that the system

encountered a pr

The keypad key will stop the buzzer in all cases,

but it will only turn off the red LED if the problem

that triggered the alarm has been resolved

from the remote bo

problem has been solved.

from being «abandoned» by default.

OPERA

SANICUBIC® 2 Pro/SANICUBIC® 2 XL REMO

CONTR

RAZ Alarme

LED

GREEN: Pow

RED: Alarm

BUTTON

Manual motor

activation

Alarm reset

Y

Mains supply

Red LED

alarme

Manual

activation

Y

mains supply

Red LED:

alarm

Manual

activation

Motor 1

Manual

activation

Motor 2

5