Maintenance and care

29

Regular checks

Check safety devices regularly, (at least 1x annually), to ensure they function correctly (e.g. BGR 232).

Safety devices that are sensitive to pressure (e.g. safety switch unit) should be checked every four weeks to ensure that they function correctly;

see EN 60335-2-95.

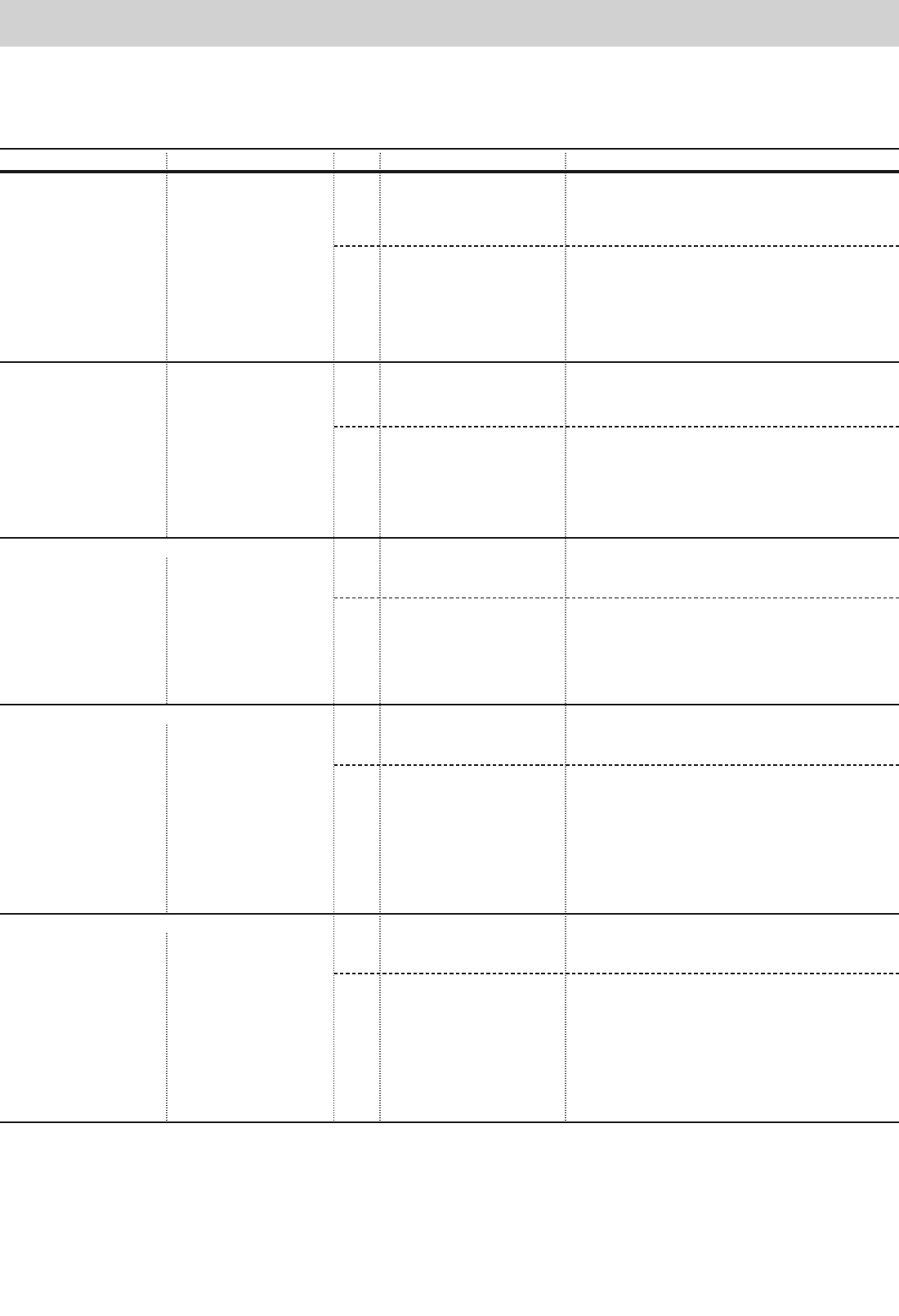

Test Behaviour yes/no Remedy

Door wing to stop when

closing with a 50 mm high

object.

Operator reverses when

encountering the object

yes

no

• Leave all settings as they are.

• Reduce the force tolerance. Decrease the setting with

TorMinal. Beforehand, open and close the door

completely 2x under supervision.

See section on “Setting maximum force”

• Adjust door, call a specialist!

Power switch-off

Procedure as described in

the section on “Emergency

release”.

Emergency release can be

easily activated (pull 1x,

operator is unlocked)

yes

no • Adjust end switch for door CLOSED, or activate back-

jump (DIP switch 6 ON).

• Repair emergency release.

• Check door, see maintenance instructions for the door.

Emergency Release

Open/close door and

activate the strip in the

process.

Behaviour of the door as set

on DIP switch 1.

Safety LED lights up

yes

no • Check wiring, tighten terminal connection.

• Correctly adjust DIP switch

• Remove door operator from operation and ensure that

it cannot restart by accident. Contact after-sales

service!

Safety contact strip if present

Open/close door and

activate the photoelectric

cell in the process.

Behaviour of the door as set

on DIP switch 1.

Safety LED lights up

yes

no • Check wiring, tighten terminal connection.

• Set DIP switch correctly

• Clean photoelectric cell

• Correctly adjust photoelectric cell

• Remove door operator from operation and ensure

that it cannot restart by accident. Contact after-sales

service!

Photoelectric cell, 1 if present

Possible cause

• Force switch-off functions

without limitations

• Force tolerance set too high.

• Door is incorrectly adjusted

• Everything is in order!

• Operator pushes the door

closed. Door and operator

mechanisms are strained.

• Emergency release is

defective.

• Door jams

• Everything is in order!

• Broken cable, loose terminal

• DIP switch incorrectly

adjusted

• Strip is defective

• Everything is in order!

• Broken cable, loose terminal

• DIP switch is set incorrectly

• Photoelectric cell is dirty

• Photoelectric cell is out of

adjustment (bent bracket)

• Defective photoelectric cell

Open/close door and acti-

vate the photoelectric cell in

the process.

Door stops Red signal

lights flash rapidly Next

command, operator

moves in door CLOSED.

Safety LED lights up

yes

no

• Check wiring, tighten terminal connection.

• Set DIP switch correctly

• Clean photoelectric cell

• Correctly adjust photoelectric cell

• Remove door operator from operation and ensure that

it cannot restart by accident. Contact after-sales

service!

Photoelectric cell 2 if present

• Everything is in order!

• Broken cable, loose terminal

• DIP switch is set incorrectly

• Photoelectric cell is dirty

• Photoelectric cell is out of

adjustment (bent bracket)

• Defective photoelectric cell