9

GB

Unpacking Y

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its features and

functions

• Ensure that all parts of the tool are present and in good condition. If any parts are missing

or damaged, have such parts replaced before attempting to use this tool

Before Use

WARNING:

accessories, or making any adjustments.

IMPORT: Ensure the blade is securely fitted before first use. See

Auxiliary Handle

• Fit the

• Adjust the Auxiliary Handle (1) angle position by loosening the 2

adjusting and re-tightening the bolts

Dust extraction

• This tool should be connected to a workshop dust extraction system or vacuum cleaner via

its Dust Port (15)

• If both are unavailable, the supplied dust bag needs to be fitted,

Port

Note: If using the dust bag,

bag when it is half full.

Adjusting the depth of cut

The tool features a T

a wide range of biscuit dowels or plates. See Biscuit guide below.

It is recommended to calibrate the tool using the size of biscuit you will mainly be using.

typical biscuit size is #10.

1. Select position ‘10’ by rotating the

Indicator (10)

2. Push forward on the Auxiliary Handle (1) until the Depth Stop (13) contacts the

(Image B) and measure the length of the exposed blade protruding from the Blade Slot

(28). Ensure one Blade

the Saw Blade (32) so a Blade T

surface of the Blade Slot

3. The measurement should be 10mm for #10 as indicated in the chart below.

loosen the Depth Stop Locking Nut (14) and adjust the Depth Stop to reduce or extend its

length to the required 10mm blade depth

4. Once correctly set tighten the Depth Stop Locking Nut

WARNING:

Note:

accurate being the position used for calibration.

Note:

• Measurements are approximate

Adjusting the cutting height

Note:

cutting height needs to be adjusted to half the thickness of the material.

• The cutting height with the fitted Fence (30) can be adjusted from 0 – 40mm.

1. Release the Fence Locking Knob (29)

2. Position the Fence at the required height using the F

3. Tighten the Fence Locking Knob to lock at the height required

Setting the fence angle

The Fence (30) has 90° of angle adjustment,

45° and 90° for angled cuts (image C).

T

1. Release the

2.

3.

Note: Check the F

in damage to the workpiece or the machine if it moves during use

Note:

necessary,

Operation

IMPORT: It is recommended to use two hands where possible when operating the tool.

Hold the Main Handle (18) of the jointer in one hand, with a finger resting comfortably on the

On/Off T

securely held.

IMPORT: Check the guard mechanism is operating smoothly and correctly before actual

use.

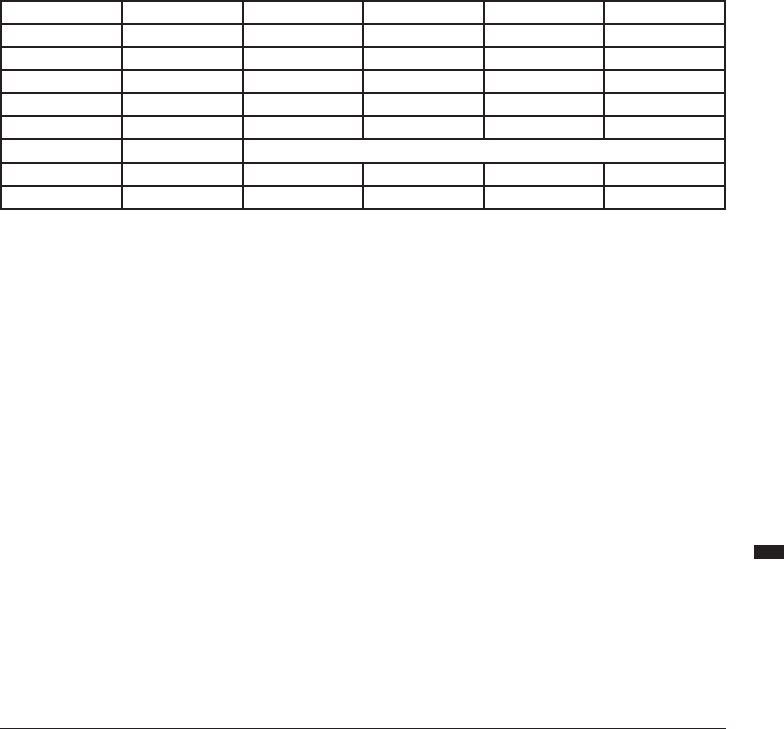

Position Marking Biscuit Width Length Thickness Cutting Depth

0 #0 15-16mm (5/8") 44-47mm (1-13/16") 4mm (19/128") 8mm (5/16")

10 #10 19mm (13/16") 53-54mm (2-1/16") 4mm (19/128") 10mm (3/8")

20 #20 25mm (15/16") 56-60mm (2-5/16") 4mm (19/128") 12.5mm (1/2")

S #20 25mm (15/16") 56-60mm (2-5/16") 4mm (19/128") 13mm (1/2")

D S6 30mm (1-1/8") 85mm (3-3/8") 4mm (19/128") 14.7-15mm (19/32")

MAX N/A T

NOT COMPA #H9 12mm 38mm 3mm 6-7mm (1/4")

NOT COMPA T

Biscuit guide

Switching on and off

• T

• Release the On/Off T

Notes:

• In order to cut biscuit slots into the workpiece as required, first set up the tool according to

the ‘Before Use’ instructions (above),

the required cutting points (Fig.

• The tool features multiple indicators to assist in positioning the tool against the workpiece.

The Face Centre Indicator (5) and Fence Blade Centre Indicator (7) indicate the centre of

the blade.

not the outer edges of the blade, this is indicated further back on the fence.

Indicator (26) on the side of the base indicates the blade height position for the standard

4mm thickness blade

• It is important that the workpieces are accurately marked. It may be easier to loosely

assemble the two pieces together in exactly the required position and mark with a pencil

across both pieces, and then cut the slots.

fitted, before marking again where subsequent biscuits are required.

position in the wood is preferable for the first slot

• There is a tolerance when joining wood with biscuits as slots can be extended if necessary

but it is better to work accurately and measure frequently

• Dowels can be placed in a wide range of positions when joining wood pieces (Fig. I) and if

necessary where biscuits are needed on multiple faces enlarged wider slots (Fig. III) can be

used to allow a workpiece to connect on multiple sides more easily

• The workpiece will need to be clamped to the workbench,

a non-slip mat between the workpiece and workbench surface will be sufficient in some

instances

1. Select the correct biscuit size on the T

2. Hold the body of the machine with one hand so that a finger rests on the On/Off T

Switch (17)

3. Carefully align the tool markings with the pencil marks on the workpiece and position the

tool in readiness to cut the slot

4. Position the machine against the workpiece so that the Face (19) and the underside of the

Fence (30) are fully in contact with the workpiece

5. Press down on the front of the Fence with the fingers of your other hand to hold the tool in

position, and check there are no gaps under the Face or underside of the F

329697_Z1MANPRO1.indd 9 29/11/2016 17:03