21

ENGLISH

20

for the saf

course of such use.

Operat

The machine is used in the commercial sect

the operator of the machine is subject t

obligations regar

The operator

-

regulations.

-

additional dangers

-

operation.

-

machine, whether the oper

by the operat

and regulations.

-

operation, maintenanc

clear¬ and unambiguous manner

-

have read and under

Moreover

handling the machine at regular intervals and be

informed about pot

-

with the prescribed and rec

devices.

-

the machine is always in a technically perf

-

intervals, and that all safety mechanisms of the

machine are regularly controlled for completeness and

functionality

2.4 Personnel r

Fundamentals

Any operation with the machine may only

by the persons, capable of performing their work properly

and reliably and

-

response capability is aected, e.g.,

medicines.

-

always adhere to the

specic regulations.

WARNING:

Risk of injury for

Improper operation can result in signicant personal and

material damage.

Any operations must be only carried out by

having required training, knowledge and

Qualied electricians

As a matter of principle, all works on the electrical

installations must be carried out by qualied electricians.

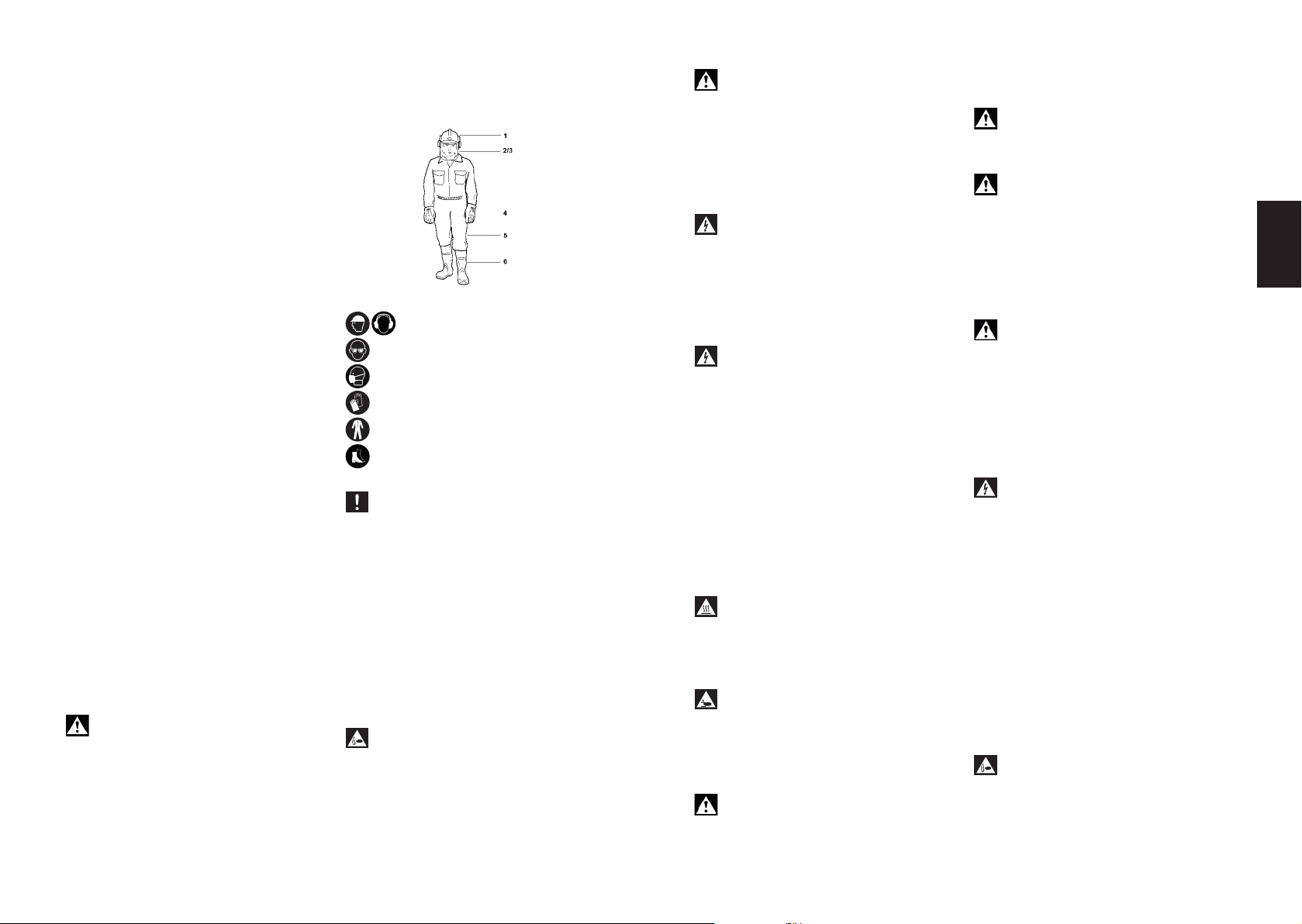

2.5 Personal pr

Wearing personal prot

the work.

1. Helmet with ear pr

2. Visor or prot

3.

4.

5. Suitable pr

6. Protectiv

NOTE!

It is prohibited to we

rotating p

danger cre

the intended protection.

2.6 Dangers

The machine has undergone a risk review

the identied

Nevertheless, the machine poses residual risks described in

the following section.

-

here and in the chapters about handling¬ t

damage

2.7 Risks

CAUTION!

Risk of cut injuries!

Reaching into r

-

circumstanc

-

-

-

CAUTION!

Risk of injury by ying clippings or tool parts!

-

working with open diamond

inappropriate diamond

injuries.

-

-

-

the material to be cut.

CAUTION!

Risk of injury by pinching in movable p

Failur

lead to

-

-

-

-

(for table saw machines).

DANGER!

Danger to lif

T

individual components can be

Disconnect the machine from the pow

any work on the electric system. Verify that the syst

disconnected from power supply.

-

and repair oper

being rest

-

immediately and arr

-

-

defective fuses.

-

-

out by qualied electricians.

CAUTION!

Risk of

-

-

-

down to the

CAUTION!

Danger of injuries caused by special

eects

Failur

may lead to he

protective gloves. T

examinations ‘G20‘

CAUTION!

Risk of

dust and cutting water or slurry!

Failur

to damage to he

Renew the cutting water re

Connect water supply

CAUTION!

Risk of injury due t

Work in

injuries. Provide for

WARNING:

Danger to lif

safety devices!

Inoperable, bypassed or disabled

protect from haz

injuries.

Before commenc

safety devices are properly installed and

Never disable

Ensure that the

WARNING:

Risk of injury due t

Wrong spare parts can seriously

cause damage and malfunction up to total failur

As a matter of principle, only original spare p

be used. Original spare parts can be obtained via an

authorized dealer or directly fr

2.8 Signage

Danger from electric current!

DANGER!

Danger to life fr

T

-

threatening. Disc

supply before any work on the electric system.

-

supply before maintenance, cleaning and

operations and secure the machine ag

restart

-

immediately and arr

-

-

defective fuses.

-

-

out by qualied electricians¬.

-

VDE0701.

CAUTION!

Risk of cut injuries!

Reaching into mo

-

circumstanc

-

blade.