16

ENGLISH

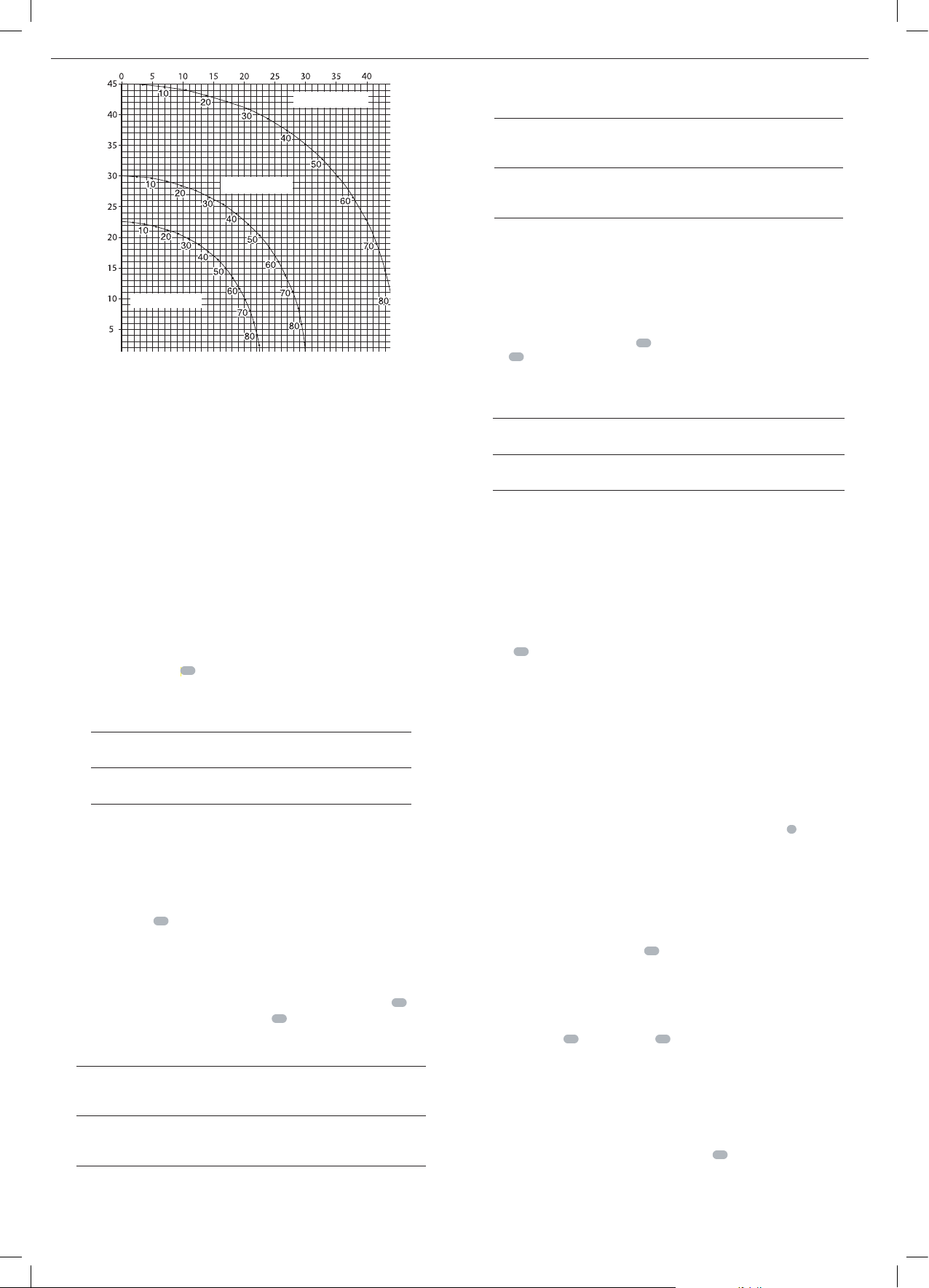

SET THIS BEVEL ANGLE ON SAW

SET THIS MITER ANGLE ON SAW

ANGLE OF SIDE OF BOX (ANGLE"A")

SQUARE BOX

6 SIDED BOX

8 SIDED BOX

• Select the desired angle A (Fig.S) of your project and locate that angle on the appropriate

arc in thechart.

• From that point follow the chart straight down to find the correct bevel angle and straight

across to find the correct mitreangle.

• Set your saw to the prescribed angles and make a few trial cuts. Practise fitting the cut

piecestogether.

Example: To make a 4-sided box with 26° exterior angles (Angle A, Fig.S), use the upper right

arc. Find 26° on the arc scale. Follow the horizontal intersecting line to either side to get mitre

angle setting on saw (42°). Likewise, follow the vertical intersecting line to the top or bottom

to get the bevel angle setting on the saw (18°). Always try cuts on a few scrap pieces of wood

to verify the settings on thesaw.

Cutting Base Moulding (Fig. J, T)

ALWAYS MAKE A DRY RUN WITHOUT POWER BEFORE MAKING ANYCUTS.

To complete straight 90° cuts, position the wood against the fence and hold it in place as

shown in FigureT. Turn on the saw, allow the blade to reach full speed and lower the arm

smoothly through thecut.

Cutting Base Molding from 76 mm to 171 mm High Vertically Against

theFence

NOTE: Use the slide lock lever 20 , shown in FigureJ, when cutting base molding measuring

from 76 mm to 171 mm high vertically against thefence.

Position material as shown in FigureT.

Inside corner Outside corner

Left side Mitre left 45°

Save left side of cut

Mitre right 45°

Save left side of cut

Right side Mitre right 45°

Save right side of cut

Mitre left 45°

Save right side of cut

Material up to 171 mm (6.75") can be cut as describedabove.

Cutting Crown Moulding (Fig. A, U1, U2)

Your mitre saw is well suited to the task of cutting crown moulding. In order to fit properly,

crown moulding must be compound mitred with extremeaccuracy.

Your mitre saw has special pre-set mitre latch points at 31.62° left and right for cutting crown

moulding at the proper angle and bevel stop pawls at 33.86° left and right. There is also a

mark on the bevel scale17 at 33.9°. The chart below gives the proper settings for cutting

crownmoulding.

NOTE: Pretesting with scrap material is extremely important!

Instructions for Cutting Crown Moulding Laying Flat and Using

the Compound Features (Fig. U1)

1. Moulding should lay flat with the broad back surface down on the sawtable60 .

2. Place the top of the moulding against the fence16 .

3. The settings below are for 45° sprung crownmoulding.

Inside corner Outside corner

Left

side

Bevel left 30°

Mitre table set at right 35.26°

Save left end of cut

Bevel right 30°

Mitre table set at left 35.26°

Save left end of cut

Right

side

Bevel right 30°

Mitre table set at left 35.26°

Save right end of cut

Bevel left 30°

Mitre table set at right 35.26°

Save right end of cut

The settings below are for crown moulding with 52° angles at the top and 38° angles at

thebottom.

Inside corner Outside corner

Left

side

Bevel left 33.9°

Mitre table set at right 31.62°

Save left end of cut

Bevel right 33.9°

Mitre table set at left 31.62°

Save left end of cut

Right

side

Bevel right 33.9°

Mitre table set at left 31.62°

Save right end of cut

Bevel left 33.9°

Mitre table set at right 31.62°

Save right end of cut

Alternative Method for Cutting Crown Moulding

Cutting crown moulding using this method does not require a bevel cut. Minute changes in

the mitre angle can be made without affecting the bevel angle. When corners other than 90°

are encountered, the saw can be quickly and easily adjusted forthem.

Instructions for Cutting Crown Moulding Angled Between the

Fence and Base of the Saw for All Cuts (Fig. U2)

1. Angle the moulding so the bottom of the moulding (the part which goes against the wall

when installed) is against the fence16 and the top of the moulding is resting on the saw

table60 .

2. The angled “flats” on the back of the moulding must rest squarely on the fence and

sawtable.

Inside corner Outside corner

Left side Mitre right at 45°

Save right side of cut

Mitre left at 45°

Save right side of cut

Right

side

Mitre left at 45°

Save left side of cut

Mitre right at 45°

Save left side of cut

Special Cuts

WARNING: Never make any cut unless the material is secured on the table and

against thefence.

Aluminum Cutting (Fig. V1, V2)

ALWAYS USE THE APPROPRIATE SAW BLADE MADE ESPECIALLY FOR CUTTINGALUMINUM.

Certain workpieces may require the use of a clamp or fixture to prevent movement during the

cut. Position the material so that you will be cutting the thinnest cross section, as shown in

FigureV1. FigureV2 illustrates the wrong way to cut theseextrusions.

Use a stick wax cutting lubricant when cutting aluminum. Apply the stick wax directly to the

saw blade46 before cutting. Never apply stick wax to a moving blade. The wax provides

proper lubrication and keeps chips from adhering to theblade.

Bowed Material (Fig. W1, W2)

When cutting bowed material always position it as shown in FigureW1 and never like that

shown in Figure W2. Positioning the material incorrectly will cause it to pinch theblade.

Cutting Plastic Pipe or Other Round Material

Plastic pipe can be easily cut with your saw. It should be cut just like wood and CLAMPED OR

HELD FIRMLY TO THE FENCE TO KEEP IT FROM ROLLING. This is extremely important when

making anglecuts.

Cutting Large Material (Fig. X)

Occasionally you will encounter a piece of wood a little too large to fit beneath the lower

guard. If this occurs, place your right thumb on the upper side of the guard1 and roll the

guard up just enough to clear the workpiece, as shown in FigureX. Avoid doing this as much

as possible, but if need be, the saw will operate properly and make the bigger cut. NEVER TIE,

TAPE, OR OTHERWISE HOLD THE GUARD OPEN WHEN OPERATING THISSAW.

Special Set-up for Wide Crosscuts (Fig. Y1, Y2)

Your saw can cut very wide (up to 409 mm) workpieces when a special set-up is used. To set

the saw up for these workpieces, follow these steps:

1. Remove both left and right sliding fences from the saw and set aside. To remove them,

unscrew the fence adjustment knobs63 several turns and slide each fence outward.

Adjust and lock the mitre control so that it is at 0°mitre.

2. Make a platform using a piece of 38 mm thick particleboard or similar flat strong 38 mm

thick wood to the dimensions: 368 x 660 mm. The platform must be flat, otherwise the

material could move during cutting and causeinjury.

3. Mount the 368 x 660 mm platform to the saw using four 76.2 mm long wood screws

through the holes62 in the base fence61 (Fig. Y1). Four screws must be used to

properly secure the material. When the special set-up is used, the platform will be cut into

two pieces. Ensure the screws are tightened properly, otherwise material could loosen and

cause injury. Ensure the platform is firmly flat on the table, against the fence, and centred

evenly from left toright.

WARNING: Ensure the saw is mounted firmly to a stable flat surface. Failure to do so

could cause the saw to be unstable and fall causing personalinjury.

4. Place the workpiece to be cut on top of the platform mounted to the table. Ensure the

workpiece is firmly against the back of the base fence61 (Fig. Y2).

5. Secure the material before cutting. Cut slowly through the material using a out-down-

and-back motion. Failure to clamp securely or cut slowly could result in the material

coming loose and causinginjury.