27

Lithium manual program

The charger automatically sets the charge current of 1C based on this information.

When you connect the pack to the charger and start the charge process, the charge current

starts at 0.00 A and slo

charger does not reach the current you have set, because the charge program constantly

monitors the battery voltage in order to prevent the pack inflating, provided that the voltage of

the individual cells in the pack is the same.When the charger automatically reduces the charge

current, the screen displays the message „END “, alternating with the reduced charge current.

The fundamental rule is that Lithium-based batteries may ONLY be charged using

special chargers, and the charge program must be set up correctly in terms of final

charge voltage and capacity for the battery type in use. The charge process is

fundamentally different to that required for Ni-Cd or Ni-MH batteries, and is termed

a constant current / constant voltage method. The charge current required varies

according to the batterset automatically by the charger.

batteries are usually charged at the 1C rate (1C charge rate = half capacity as charge current. Example:

battery capacity 1500 mAh: 1C charge current = 1500 mA = 1.5 A). For this reason it is essential to set

the charger to the battery capacity instead of the charge current. When the battery on charge reaches

the specific final voltage which is appropriate to the battery type, the charger automatically reduces the

charge current in order to prevent the battery exceeding the final permissible voltage. If the battery

manufacturer states a charge current lower than the 1C rate, then the capacity (charge current) must be

reduced accordingly

We recommend the use of the Micr

batteries are charged optimally

Problems caused by mistreating batteries:

It is very dangerous to overcharge Lithium-Ion batteries, as they tend to react by gassing, overheating

and even exploding. If the final charge voltage of 4.1 V / cell (Lithium-Ion) or 4.2 V / cell (Lithium-Polymer

and Lithium-Manganese) is exceeded by more than 1%, the lithium ions in the cell start to change into

metallic lithium. This material reacts very violently with the water in the electrolyte, and this can result in

the cell exploding. On the other hand it is also important to avoid terminating the charge process before

the final charge voltage is reached, since this reduces the effective capacity of the Lithium-Ion cell

markedlythe charge at just 0.1 V under the threshold means a capacity loss of around 7%.

Lithium batteries must not be deep-discharged, as this leads to a rapid loss of capacity

irreversible; it is absolutely vital to avoid discharging the batteries to below 2.5 V / cell.

Caution: the cell type, cell capacity and cell count set on the charger must always

the battery to be charged; if you make a mistake, the battery could explode! Never connect a

Lithium-based battery to the charger if it features an integral charge circuit! Always place your

Lithium batteries on a non-flammable surface for charging

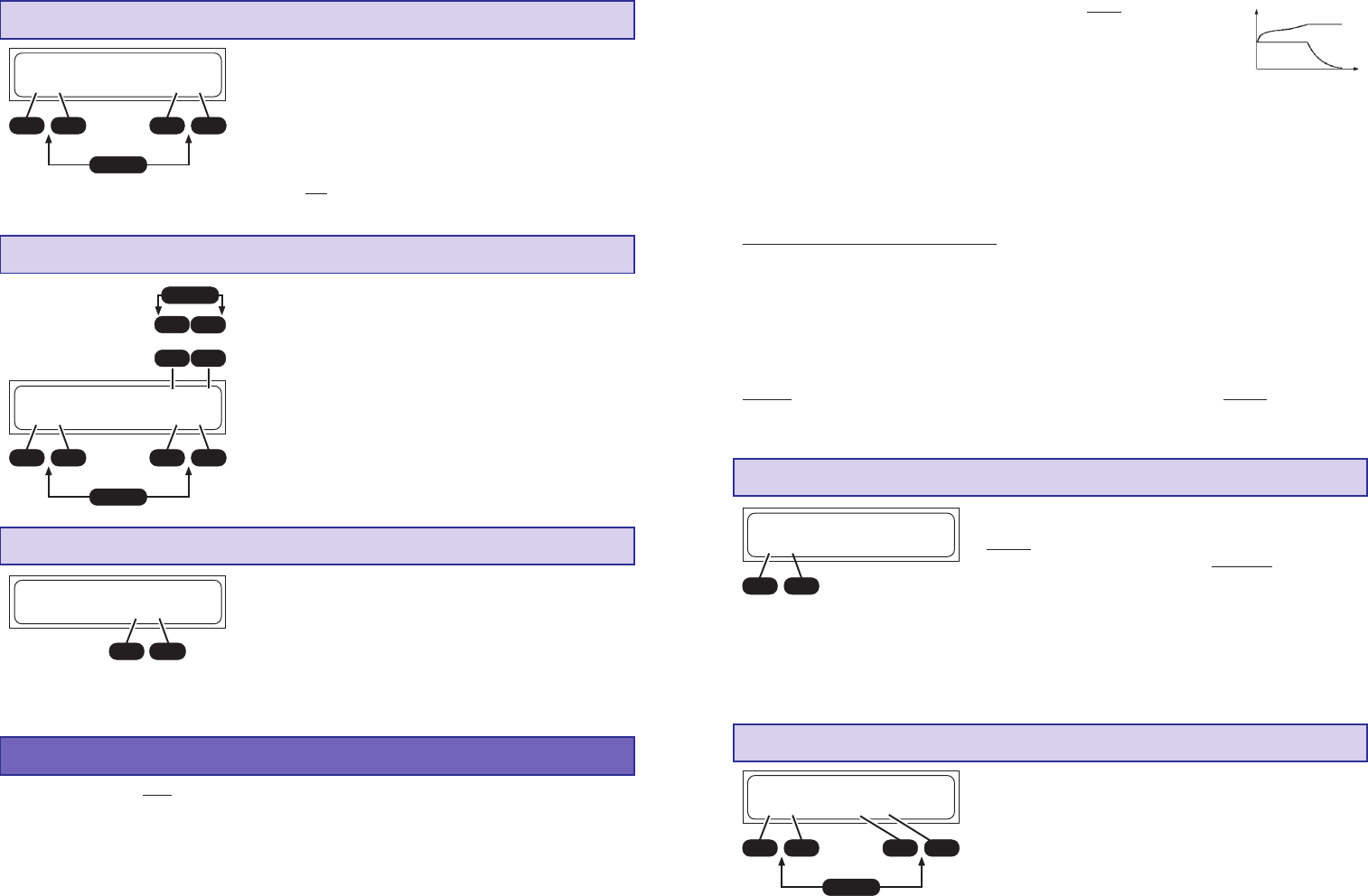

This program charges the battery using the capacity

(charge current) which you set.

Before you initiate the actual program you must set the

capacity of the pack (and thus the

maximum

current - range 50 … 7000 mAh) using the INC / DEC

buttons.

___________ _

___________ _

LiPo manu

C:2500

DECINC

+

-

Lithium discharge program

The purpose of this program is to determine the residual

capacity of a Lithium pack which has not been fully

discharged.

The program discharges the pack using the set discharge

current (0.10 ... 100 A, left of screen) down to the set final

discharge vcell, right of screen). It

is not possib

per cell, otherwise the battery will suffer permanent

damage.

___________ _

___________ _

LiPo disc

1.00A 2.5V/

DECINC

+

-

DECINC

+

-

ENTER

INC

___________ _

___________ _

DEC

INC

+

-

DEC

INC

+

-

ENTER

DEC

DEC

INC

ENTER

Ni-MH discharge program

___________ _

___________ _

NiMH disch

1.00A 4.8V

DECINC

+

-

DEC

INC

+

-

ENTER

13. Lithium programs

Ni-MH-Delta-Peak (-

∆

∆

∆ Peak)

trigger voltage

It is possible to adjust the trigger voltage (in mV per cell!) of

the automatic termination circuit for Ni-MH batteries.

Howe

drop than Ni-Cd cells, and a practical range has proved to

be 5 ...

is a danger of ov

a danger of premature termination.

We recommend that you carry out a series of test charges

to establish the ideal trigger value for your batteries.

Ni-MH conditioning program

These programs are only suitable for charging and discharging Lithium-Ion batteries with a

voltage of 3.6

3.7 V cell.

to other battery types. Ho

handling strategies: they must be charged and discharged using specific methods, otherwise

they will be damaged, and can be dangerous

observed at all times when handling these batteries. Specific information and safety notes will

also be f

The typical purpose of this program is to determine the

residual capacity of a tr

or to discharge the pack to a defined level.

In this program the charger discharges the pack using the

set discharge current (0.10 ... 1.00 A, left of screen) until its

voltage f

right of screen).

The set final discharge voltage should be a value of around

0.8 ...

per cell, in order to av

deep-discharged. Deep-discharging a pack runs the risk of

rev

This program is designed to optimise the capacity of a

battery

At top right you can use the INC or DEC button to determine

whether the conditioning program is to start with a charge or

discharge cycle. After this you set the number of cycles

from 1 to 5 (e.g., if you set three cycles, the pack will be

charged and discharged three times).

charges the battery using the set discharge current stated

on the right of the screen (0.10 ... 1.00 A), and then rech-

arges it using the charge current (0.1 ... 7.0 A) shown on

the left of the screen.charge process is ter

automatically in accordance with the values already set for

„Ni-MH Delta P

out the values for the individual cycles is described in the

section „Screen displays“.

or

___________ _

___________ _

NiMH delta

volt =

DECINC

+

-

charge time

current

voltage

NiMH cy

C:2.5 E