ENGLISH 12

AAlways unplug the appliance when cleaning it and

when performing maintenance work. Do not use ammable

liquids to clean the machine.

Cleaning the dishwasher

Any marks on the inside of the appliance may be remo

a cloth dampened with water and a little vinegar

The external surfaces of the machine and the contr

can be cleaned using a non-abrasive cloth which has been

dampened with water

Pre

Always keep the door of the appliance ajar in order to avoid

moisture fr

Clean the seals around the door and detergent dispensers

regularly using a damp sponge. This will avoid food becoming

trapped in the seals, which is the main cause behind the

formation of unpleasant odours.

Cheking the water supply hose

Check the inlet hose regularly for brittleness and cr

damaged, replace it b

Sales Service or your specialist dealer

type:

ENGLISH

10

Cleaning and maint enanc e

A TTENTION: Always unplug the appliance when cleaning it

and when performing maintenance work. Do not use flammable

liquids to clean the machine.

CLEANING THE DISHW ASHER

Any marks on the inside of the appliance may be

removed using a cloth dampened with water and

a little vinegar .

The external surfaces of the machine and the

c o n t r o l panel can be cleaned using a non-abrasive

cloth which has been dampened with water . Do

not use solvents or abrasive products.

PREVENTING UNPLEASANT ODOURS

Always keep the door of the appliance ajar in order to avoid mo -

isture from forming and being trapped inside the machine.

Clean the seals around the door and detergent dispensers regu -

larly using a damp sponge. This will avoid food becoming trapped

in the seals, which is the main cause behind the formation of

unpleasant odours.

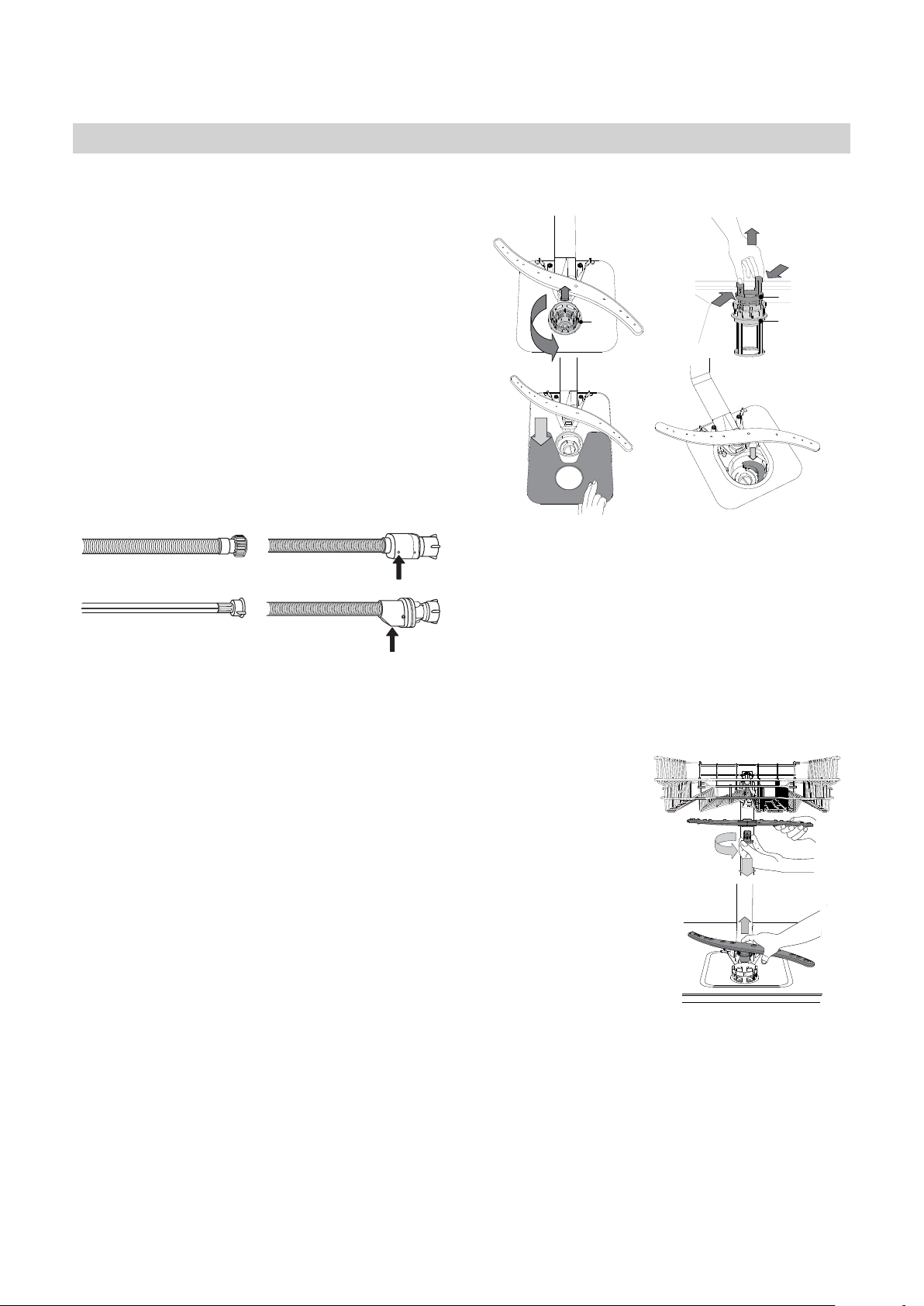

CHEKING THE W A TER SUPPL Y HOSE

Check the inlet hose regularly for brittleness and cracks. If dama -

ged, replace it by a new hose available through our After-Sales

Service or your specialist dealer . Depending on the hose type:

If the inlet hose has a transparent coating, periodically check if

the colour intensifies locall . If yes, the hose may have a leak and

should be replaced.

For water stop hoses: check the small safety valve inspection

window (see arrow). If it is red, the water stop function was trig -

gered, and the hose must be replaced by a new one.

For unscrewing this hose, press the release button while unscre -

wing the hose.

CLEANING THE W A TER INLET HOSE

If the water hoses are new or have not been used for an exten -

ded period of time, let the water run to make sure it is clear and

free of impurities before performing the necessary connections. If

this precaution is not taken, the water inlet could become blocked

and damage the dishwasher .

CLEANING THE FIL TER ASSEMBL Y

Regularly clean the filter assembly so that the filters do not clo

and that the waste water flows away correctl .

Using dishwasher with clogged lters or foreign objects inside l -

tration system or sprayarms may cause unit malfunction resulting

in lose of performance, noisy work or higher resources usage.

The filter assembly consists of three filters which remove foo

residues from the washing water and then recirculate the water:

to obtain the best washing results, you need to keep them clean.

The dishwasher must not be used without lters or if the

lter is loose.

At least once per month or after each 30 cycles, check the filter

assembly and if necessary clean it thoroughly under running

water , using a non-metallic brush and following the instructions

below:

1. T urn the cylindrical filter A in an anti-clockwise direction and

pull it out (Fig 1) .

2. Remove the cup filter B by exerting a slight pressure on the

side flaps (Fig 2) .

3. Slide out the stainless-steel plate filter C (Fig 3) .

4. In case you find foreign objects (such as broken glass, porc -

lain, bones, fruit seeds etc.) please remove them carefully .

5. Inspect the trap and remove any food residues. NEVER RE-

MOVE the wash-cycle pump protection (black detail) (Fig 4) .

After cleaning the filters, replace the filter assembly and fix it

position correctly; this is essential for maintaining the efficient

operation of the dishwasher .

CLEANING THE SPRA Y ARMS

On occasions, food residue may

become encrusted onto the

spray arms and block the holes

used to spray the water . It is

therefore recommended that you

check the arms from time to time

and clean them with a small

non-metallic brush.

T o remove the upper spray arm,

turn the plastic locking ring in an

anti-clockwise direction.

The upper spray arm should be

replaced so that the side with

the greater number of holes is

facing upwards.

The lower spray arm may be

removed by pulling it upwards.

W A TER SOFTENING SYSTEM

W ater softener automatically reduces water hardness, conse -

quently preventing scale buildup on heater , contributing also to

better cleaning efficienc . This system regenerates itself with salt,

therefore it is required to refill salt container when empt . Frequen -

cy

of regeneration depends on water hardness level setting - by

default regeneration takes place once per 5 Eco cycles with water

hardness level set to 3 . Regeneration process starts in final rins

and finishes in drying phase, before cycle ends

Single regeneration consumes: ~3.5L of water; takes up to 5 addi -

tional minutes for the cycle; consumes below 0.005kWh of energy .

A

A

B

C

12

34

If the inlet hose has a transpar

the colour intensies locall . If yes, the hose may have a leak and

should be replaced.

For water stop hoses: check the small safety valve inspection

window (see arr

triggered, and the hose must be r

unscre

the hose.

Cleaning the water inlet hose

If the water hoses are ne

extended period of time, let the water run to make sur

clear and free of impurities befor

connections. If this precaution is not taken, the water inlet could

become blocked and damage the dishwasher

Cleaning the lter assembly

Regularly clean the lter assembly so that the lters do not close

and that the waste water ows away corr

Using dishwasher with clogged lters or foreign objects inside

ltration system or spr

resulting in lose of performance, noisy work or higher r

usage.

The lter assembly consists of three lters which r

residues fr

to obtain the best washing results, you need to keep them clean.

The dishwasher must not be used without lters or if the

lter is loose.

At least once per

assembly and if necessary clean it thoroughly under running water

using a non-metallic brush and following the instructions belo

1. TA in an anti-clockwise direction

and pull it out (Fig 1).

2. Remove the cup lter B b

side aps (Fig 2).

3. Slide out the stainless-steel plate lter C (Fig 3).

4. In case you nd for

porc - lain, bones, fruit seeds etc.) please r

carefully.

5. Inspect the trNEVER

REMOVE the wash-cycle pump protection (black detail) (Fig

4).

After cleaning the lters, replace the lter assembly and x it

position correctly; this is essential for maintaining the ecient

operation of the dishwasher

Cleaning the spray arms

On occasions, food residue may become encrusted onto the

spray arms and block the holes used to spr

therefor

time and clean them with a small non-metallic brush.

T

in an anti-clockwise direction. The upper spr

replaced so that the side with the gr

facing upwar

The lower spr

Water softening system

Water softener automatically

reduces water har

consequently pre

scale buildup on heater

contributing also to better

cleaning ecienc . This

system regener

salt, therefor

to rell salt container

when empt . Frequency of

regener

water hardness le

by default r

place once per 5 Eco cycles

with water hardness le

to 3. Regeneration pr

starts in nal rins and

in drying phase, before cycle

ends Single regener

~3.5L of water;

takes up to 5 additional minutes for the cycle;

consumes below 0.005kWh of energy

Cleaning and maintenance