16

6.4 Adjusting the angle of

the bandsaw table

Place a set square (B) on the bandsaw

table.

The bandsaw blade must not touch the

upper and lower guide pins and back guide

rollers

during measuring.

Loosen the two knob screws (15). Adjust the

bandsaw table to form an exact right angle

with the bandsaw blade.

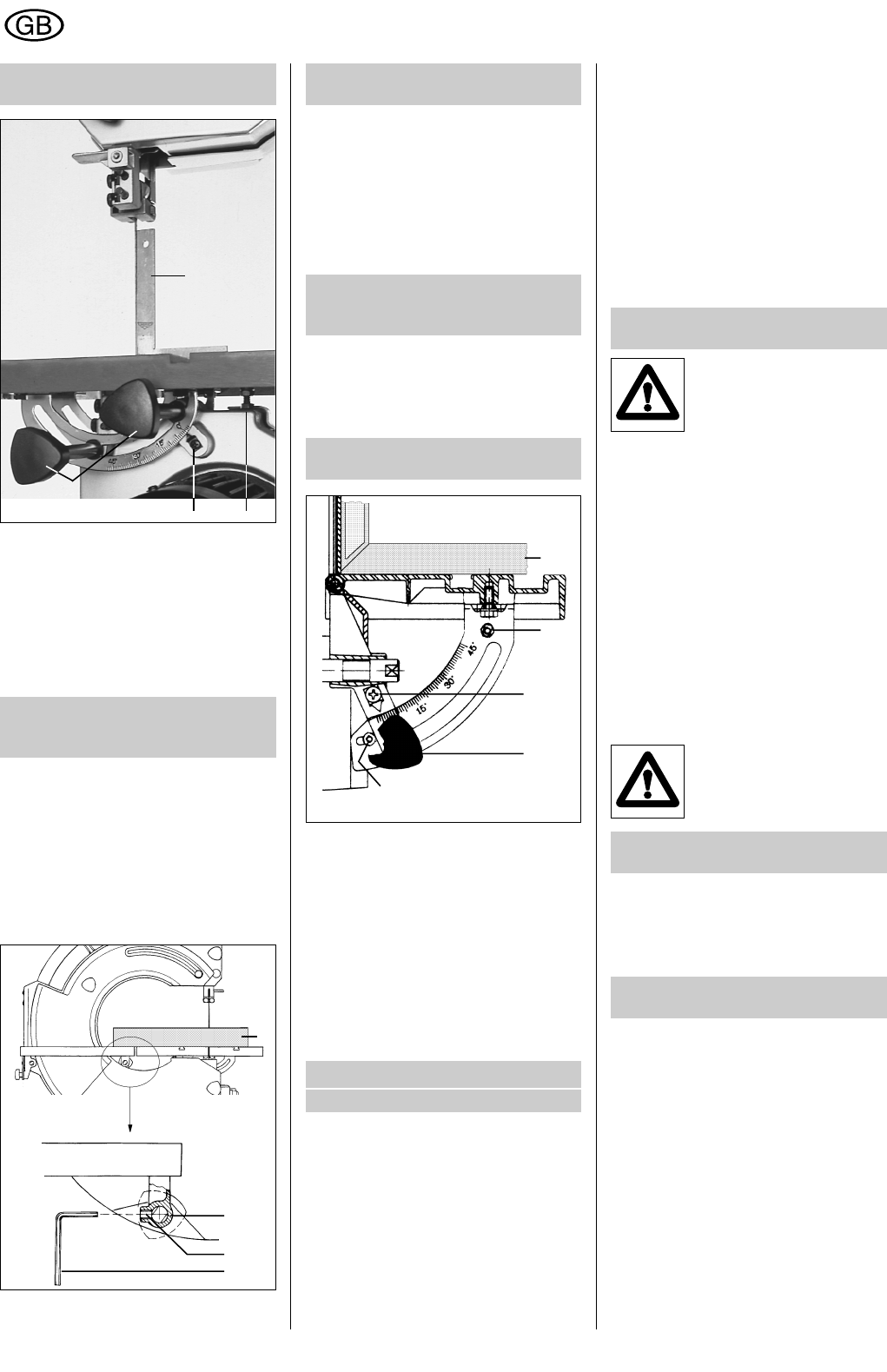

6.5 Adjusting the

graduated scale of the

bandsaw table (Fig. 4)

Adjustment of the graduated scale of the

bandsaw table (Fig. 4)

Loosen screw (36). Set the pointer to the 0o

mark and tighten the screw.

Loosen the 0° stop (37). Bring it up to the

machine casing and secure with the hexa-

gon-head lock nut.

Swivel the table to 45°. Bring the 45° stop

up to the machine casing and secure with

the hexagon-head lock nut.

6.6 Adjusting the high of

the sanding table

Lay a straight edge (A) over both tables.

Adjust the height of the sanding table to the

height of the bandsaw table.

The height of the table can be adjusted by

turning the two eccentric axes (5). Loosen

the set screws (38) with the size 4AF Allen

key (4). Loosen the knob screws if neces-

sary. Turn eccentric axis (5) with the size

13AF open-ended spanner.

6.7 Setting the distance

between the sanding table

and the sanding disc (Fig. 5)

Setting the distance between the sanding

table and the sanding disc (Fig. 5)

Loosen the set screws (38) on the left and

right table mounting. Set the distance

between table and disc to approx. 2-3 mm.

6.8 Adjusting the graduated

scale of the sanding table

Adjusting the graduated scale of the san-

ding table

Place a set square (B) over the sanding

table. Loosen the securing screw (44). Set

the sanding table to form an exact right

angle with the sanding disc and secure in

position. Slacken off the screw (43), set the

pointer to the 0° mark on the scale and

tighten the screw.

Loosen the 0° stop (45). Move it to the right

and secure in position.

Swivel the table to 45°. Loosen the 45° stop

(42), shift it down and clamp it.

7 Bandsaw blade

7.1 Bandsaw blades

Attention:

Use only sharp and properly set saw

blades.

Only machine-sharpened and correctly set

saw blades give proper cutting results.

Never use damaged saw blades.

The choice of correct bandsaw blade

width depends on the cutting operation

to be undertaken.

For cutting tight curves

with radii from 5 mm, work

only with the fine-cutting

equipment . . . . . . . . . . . . . . . . . 3 mm wide

For cutting curves with

radii from 20 mm . . . . . . . . . . . . 6 mm wide

For longitudinal and cross

cuts, cutting curves with

radii from 40 mm . . . . . . . . . . . 10 mm wide

For straight cutting, and

thick workpieces . . . . . . . . . . . 15 mm wide

7.2 Changing the

bandshaw blade (Fig. 1)

Caution:

Switch off the machine and

disconnect from the mains

supply. Remove the plug!

Unscrew the two knob screws (9) and open

the machine cover.

Slacken off the wing nut (2) on the bandsaw

table and push the screw to the right.

Open the cover (11) of the blade guard.

Turn the screw (7) securing the blade to the

left to slacken off the saw blade.

Remove the bandsaw blade and fit the new

blade around the three pulleys.

Thread the blade between the upper and

lower guide pins (13). Secure the blade with

the screw (7). Close the cover (11) and the

machine cover.

If the cover refuses to close, push the blade

guard down.

Push the screw (2) to the left and tighten

the wing nut to ensure that the grooved

bandsaw table cannot be distorted.

Always wear protective

gloves!

7.2.1 Folding the

bandsaw blade

Hold the bandsaw blade in one hand. Let it

hang down vertically and hold it to the floor

with a foot. Turn your hand through 360°(a

complete circle), as you move it down

towards the floor.

7.2.2 Unfolding the

bandsaw blade

Hold the bandsaw blade away from your

body. Then hold one loop of the blade and

the two other loops will be released. The

bandsaw blade unfolds itself.

Fig. 4

B

3736

15

Fig. 6

43

44

45

42

B

Fig. 5

A

5

38

4

ENGLISH