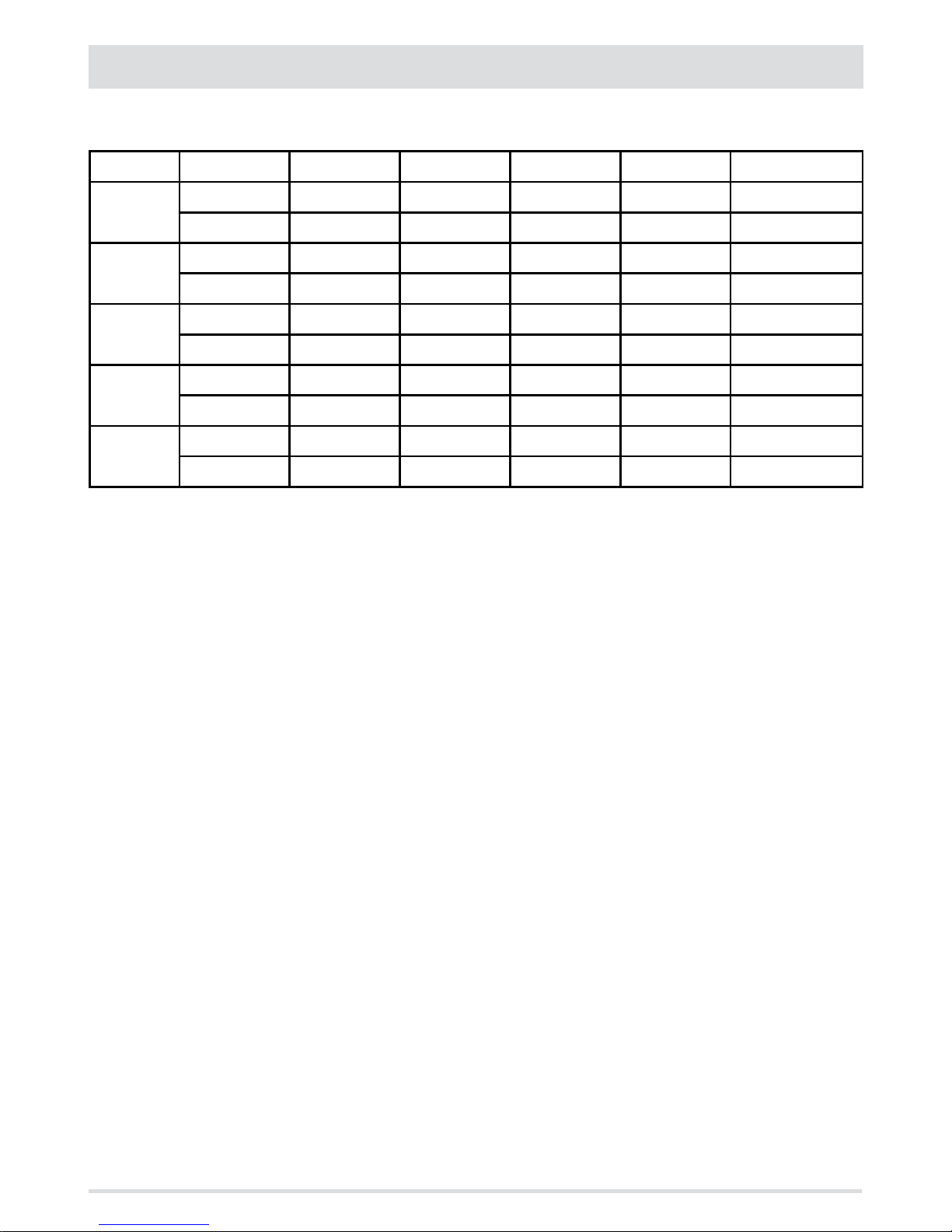

NEGATIVE PRESSURE INSIDE THE HOPPER WITH FACTORY-SET PARAMETERS AND A DRAUGHT OF 5 Pa (MINIMUM

RECOMMENDED)

POWER P1 P2 P3 P4 P5 VALUES

6 kW 13.7/14.2 Pa 15.1/15.6 Pa 17.1/17.5 Pa 19.1/19.5 Pa 22.0/22.2 Pa Draught

95°C 110°C 125°C 141°C 165°C Smoke temperature

8 kW 13.8/14.3 Pa 15.6/16.1 Pa 17.8/18.0 Pa 21.7/22.2 Pa 26.1/26.6 Pa Draught

104°C 119°C 145°C 148°C 184°C Smoke temperature

10 kW 15.9/16.3 Pa 20.4/20.9 Pa 25.8/26.3 Pa 31.8/32.3 Pa 36.5/37.0 Pa Draught

108°C °C 150°C °C 230°C Smoke temperature

12 kW 16.5/17.3 Pa 20.4/20.9 Pa 25.8/26.3 Pa 31.8/32.3 Pa 36.5/37.1 Pa Draught

118°C 127°C 155°C 172°C 195°C Smoke temperature

14 kW 17.6/18.0 Pa 19.8/20.4 Pa 23.1/23.7 Pa 28.9/29.6 Pa 37.8/38.2 Pa Draught

118°C 131°C 161°C 187°C 210°C Smoke temperature

PLEASE NOTE The indicated negative pressure readings may dier by ±1Pa based on ue gas temperature. Likewise, ue gas temperature

may dier by ±10°C based on fuel quality or appliance cleanliness.

Changing the smoke fan revolutions

In the event the installation presents problems in extracting smoke (lack of draft or even pressure in the duct), it is possible to increase

the smoke and ash extraction speed. This change resolves all the potential problems related to pellets clogging in the brazier and deposits

forming at the bottom of the brazier itself caused by poor quality fuel or fuel that produces a lot of ash. The extraction speed may be

altered between -30% to +50%, with increments of 10 percent at a time. Negative variation can be necessary if the ame is too low.

To alter this parameter, proceed as follows:

• Press the “menu” key.

• Use the arrow keys to scroll through and select “Settings”

• Press “menu” to conrm.

• Scroll with the arrows and select “Fumes rpm Var.”

• Press “menu” to conrm.

• Alter the % with the + - keys.

• Press ‘’menu’’ to conrm and ‘’esc’’ to exit.