Hold

the whe

Do

of no m

The mac

-

(materi

the bas

- to

in

- use

washers

- to sec

screw in th

nut D5.

- Insert the sc

- Completely sc

Do no screw the sc t tig dur thi job t avoi crac t

guards.

- Remove the sc.

- Secure the gua

relativ.

- Secure

R10, in.

The completel to it

intact.

T Tie

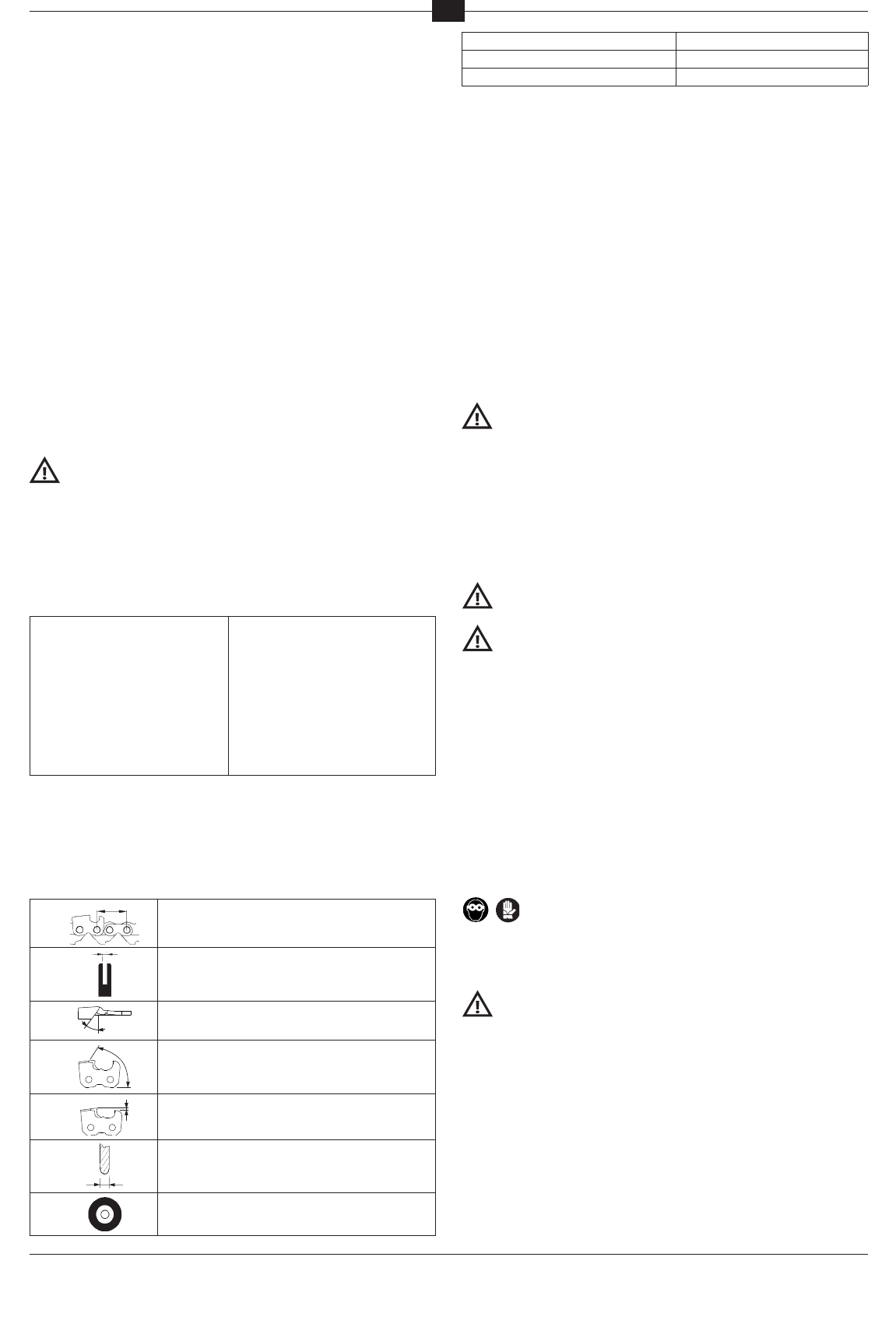

T Left cutte

Side cutti Right cut

Gullet Drive link

Depth gaug Rivet

T

Heel

Rivet hole

- Before

adjustm

chain s

- The chain ide

- Y

- Consult the C

The columns

÷ 2

Chain p

Gauge

T

Cutting

Depth g

Grindin

Grindin

Oregon Carlton

Wi S

SARP EM chain co

a -

b -

c -

d -

- Use

chain c

- Do

diamete

- Use exclusive

- Make sure the

- Loosen the sc.

- Choose t

in chai

- Insert

.

- Insert the a.

If the grinding wheel is tted with

use and put the operato

If

- Close the gua

- Stand

the

abnorma

- If this sh

whe

origina

Always

minute

nobody

- Mak

ra

- The

- The

fo

- The

mu

30

- Plug the powe

- With the machine

templat; if

Wea

- Start the gri

- Prole

caution.

- Stop the mach.

Contact with the grinding whee

burning

- Establish

link (c

-

.

gauge f.

- Look-up

related

- Tu.

cond

P00801077_R03_COMPACT_U&M_120V.indd 3 12/12/2012 14.33.43